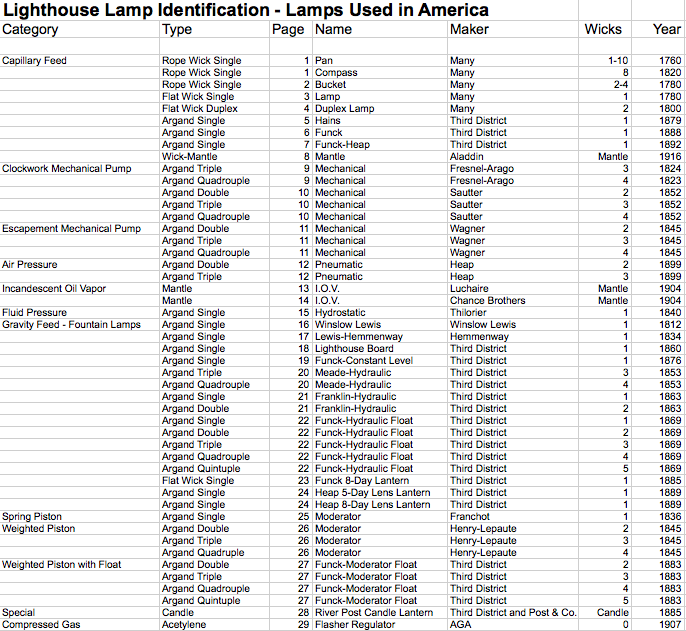

This document was commissioned by the American Lighthouse Council to assist in identifying lighthouse lamps used in America. The first page is a chart of the types of lighthouse lamps used in America with some description details and identifying the page where further details can be found for each lamp type. You can then go to that page to find photos and further details.

PAGE 1

Category: Capillary Feed

Type: Rope Wick Single

Name: Pan and Compass

Maker: Many

Year of Origin: 1760 Pan, 1820 Compass

Pan and Compass Lamps

By the 1760s, a form of Spider Lamp known as the Pan Lamp replaced the other early oil lamps in some lighthouses. The Sandy Hook light, in New Jersey, built in 1764, is reported to have used two Pan Lamps with a total of 48 oil blazes, hung from the lantern room ceiling by chains. Pan Lamps came in several forms. There were circular and rectangular pans, and a donut shaped Pan Lamp was used in the early lightships. Pan Lamps with a circular form were also known as Compass Lamps.

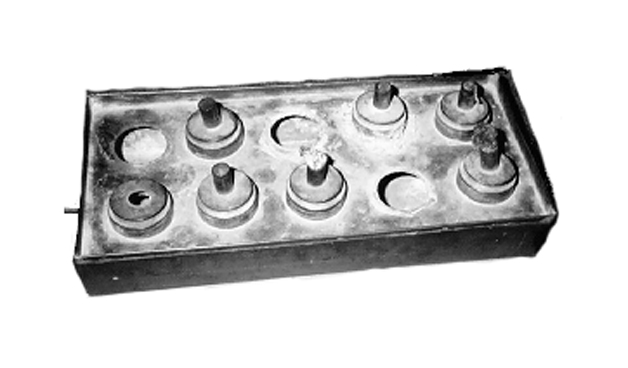

The Pan Lamp solved the problem of a limited oil supply and could operate for twelve or more hours on one fill of oil. The Pan Lamp had multiple rope wicks. The number of wicks varied from two too as many as twenty-four, with eight to ten wicks being very common. The Pan Lamp produced more light than the other early oil lamps because individual large diameter wicks were placed nearly side by side across the surface of the metal pan, and the flames could all be seen at the same time. Its main drawbacks were its relatively low light output, its massive consumption of oil, and the smoke and fumes produced within the lantern room, which at times became almost intolerable.

Pan and Compass Lamps were used for a very long time. The early light lists show a Compass Lamp with 8 wicks still in use at the Vermilion beacon light, in Ohio, in 1849. Compass Pan Lamps were the only style of lamp in use on American lightships until the mid 1850s.

PAGE 2

Category: Capillary Feed

Type: Rope Wick Single

Name: Bucket

Maker: Many

Year of Origin: 1780

Bucket Lamp

The Bucket Lamp, another form of Spider Lamp, had been available for many years and began to be used in lighthouses in the latter part of the 1700s, mainly in the smaller lighthouses, beacon, and pier-head lights. The Bucket Lamp was made of sheet metal and was cylindrical in shape, with two or four spouts protruding from its sides. Each spout carried a large diameter rope wick that extended down inside the body of the lamp into the oil. Below each spout was a similarly shaped drip catcher. The Bucket Lamp held up to an eight-quart oil supply and could operate for twelve or more hours on one fill of oil. Its main drawbacks were still the very poor light produced, the smoke and fumes, and the problem that some of the flames were hidden from view behind the bucket, when it was viewed from specific directions. The Cape Henry light used this style lamp in 1792 and burned fish oil probably from Herring. The use of Bucket Lamps lasted a long time and four were recorded as being in use in 1845, at the Cunningham Creek Beacon light in Ohio.

PAGE 3

Category: Capillary Feed

Type: Flat Wick Single

Name: Lamp

Maker: Many

Year of Origin: 1780

Flat Wick Single

Flat Wick lamps are based on the principle of capillary attraction where the fuel is raised to the flame by the wick itself. In these lamps the fuel is stored below the burner and the fibers of the wick soak up the fuel and raise it from the fuel reservoir to the top of the wick through capillary action within the fibers. These lamps were used in the fourth-order and smaller lenses.

PAGE 4

Category: Capillary Feed

Type: Flat Wick Duplex

Name: Duplex Lamp

Maker: Many

Year of Origin: 1800

Flat Wick Duplex

Flat Wick Duplex lamps are based on the principle of capillary attraction where the fuel is raised to the flame by the wick itself. In these lamps the fuel is stored below the burner and the fibers of the wick soak up the fuel and raise it from the fuel reservoir to the top of the wick through capillary action within the fibers. These lamps were used in the fourth-order and smaller lenses. The addition of the second wick allowed a brighter flame and a flame that was larger in diameter. The larger diameter flame worked within the lens to produce a greater divergence of light to the mariner.

PAGE 5

Category: Capillary Feed

Type: Argand Single

Name: Hains

Maker: Third District

Year of Origin: 1879

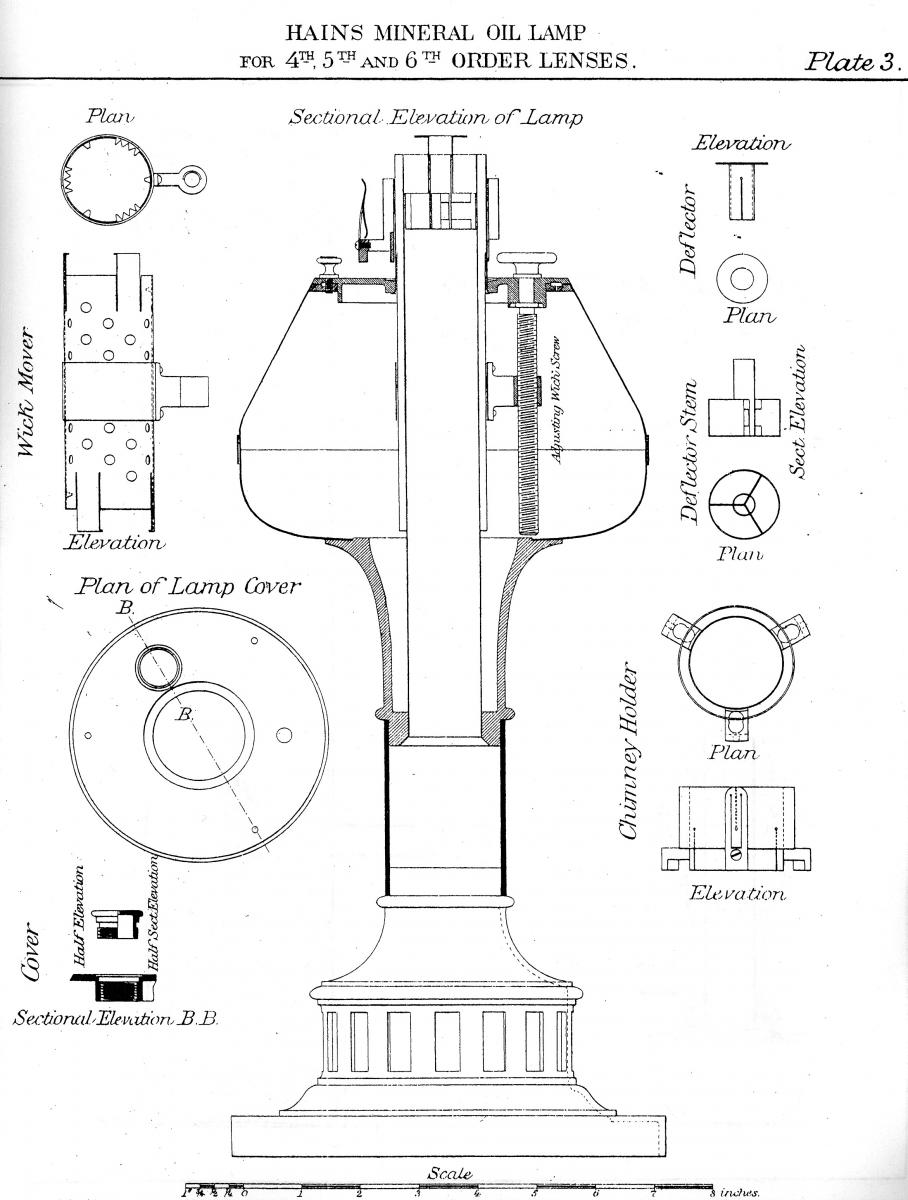

Hains Lamp

Capillary lamps are based on the principle of capillary attraction where the fuel is raised to the flame by the wick itself. In these lamps the fuel is stored below the burner and the fibers of the wick soak up the fuel and raise it from the fuel reservoir to the top of the wick through capillary action within the fibers. These lamps were used in the fourth-order and smaller lenses.

In 1879, Peter C. Hains of the Lighthouse Board was able to dramatically improve the lamps used in the fourth-order lenses in America. Hains redesigned the old fourth-order Winslow Lewis Argand style lamps and produced a smaller cleaner lamp with stands of various heights and a number of air-flow and wick height adjustments.

PAGE 6

Category: Capillary Feed

Type: Argand Single

Name: Funck

Maker: Third District

Year of Origin: 1888

Funck’s Improved Fourth-Order Lamp

In 1888, Joseph Funck was able to dramatically improve the lamps used in the fourth-order lenses in America. Funck redesigned the old Hains fourth-order lamp and produced the ‘improved-fourth-order lamp,’ which had a new flame spreader and a number of airflow adjustments.

PAGE 7

Category: Capillary Feed

Type: Argand Single

Name: Funck-Heap

Maker: Third District

Year of Origin: 1892

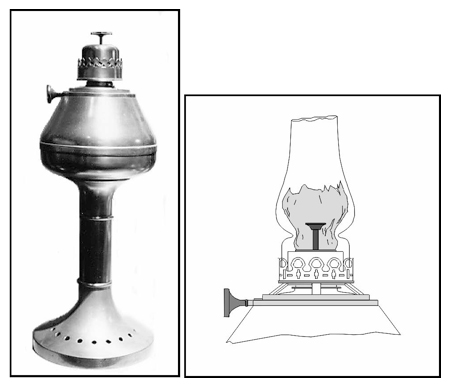

Funck-Heap Lamp

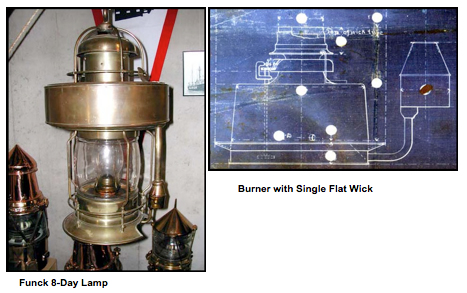

In the smaller lighthouses a lamp called the Funck-Heap lamp was introduced in 1892. It was a standard Argand lamp with a single one and one-eighth-inch diameter wick. There was a flame-spreading button in the center of the flame that got red-hot and helped to keep the flame a constant size and shape. The feeding of the wick was accomplished by a screw thread on the wick carrying tube. The Funck-Heap lamp became the standard lamp used in all fourth-order lenses in the American Lighthouse Service and was refitted into all of the lighthouses using a fourth-order lens as quickly as it could be manufactured. The same design with slight variations in the flame spreader and chimney was developed for the fifth and sixth-order lamps.

Funck-Heap 4th Order Lamp. Details of Funck-Heap 5th and 6th Order Burner.

PAGE 8

Category: Capillary Feed

Type: Wick-Mantle

Name: Mantle

Maker: Aladdin

Year of Origin: 1916

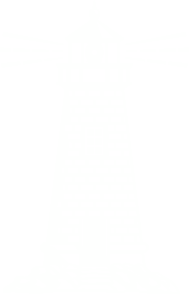

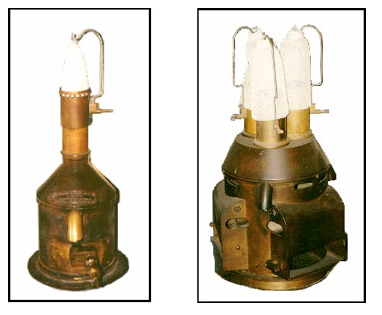

Aladdin Wick Mantle Lamp

The Aladdin Company developed a lamp using a wick to feed a mantle. This lamp was supplied instead of an Incandescent Oil Vapor (I.O.V.) Lamp in the 4th through 6th orders of lenses. The lamp was also useful in the keeper’s dwelling.

PAGE 9

Category: Clockwork Mechanical Pump

Type: Argand Triple, Quadruple

Name: Mechanical

Maker: Fresnel - Arago

Year of Origin: 1823-1824

Fresnel-Arago Clockwork-Concentric-Wick Lamps

Augustin Fresnel and François Arago used the ideas of Count Rumford and the Guyton de Morveau to design new Argand style lamps, and made a series of trials of lamps with various numbers of concentric wicks, in late 1819. It was found that a standard Argand lamp, even with multiple concentric wicks, would not perform as required, because the multiple wicks caused such great heat that the burner would melt and the wicks would quickly char. After many trials it was found that the Argand style lamp invented by Monsieur Bertrand Carcel in 1800 could be used with multiple concentric wicks.

The Carcel lamp had a double-piston-mechanical pump operated by clockwork that forced excess oil through a tube to the wick, overflowing the wick and cooling the entire burner. By December 1819, Fresnel and Arago had created a multiple-concentric-wick lamp using the Carcel cooling principal and the first triple-wick burner was operational in their laboratory. Within a few months, they also developed a quadruple-wick burner and proposed its use within the first, first-order lens that was manufactured. The quadruple-wick burner was first used in 1823 and the triple-wick burner was first used in 1824.

Fresnel Arago Quadruple-Wick Lamp.

PAGE 10

Category: Clockwork Mechanical Pump

Type: Argand Double, Triple, and Quadruple

Name: Mechanical

Maker: Sautter

Year of Origin: 1852

Sautter Mechanical Lamp

In 1852 Louis Sautter entered the lighthouse equipment business. The Sautter mechanical lamp continued to use the Carcel clockwork that had a double-piston-mechanical pump operated by clockwork, which forced excess oil through a tube to the wick, overflowing the wick and cooling the entire burner. Sautter improved the design of the Fresnel-Arago lamp burners to allow more airflow between the wicks.

PAGE 11

Category: Escapement Mechanical Pump

Type: Argand Double, Triple, and Quadruple

Name: Mechanical

Maker: Wagner

Year of Origin: 1845

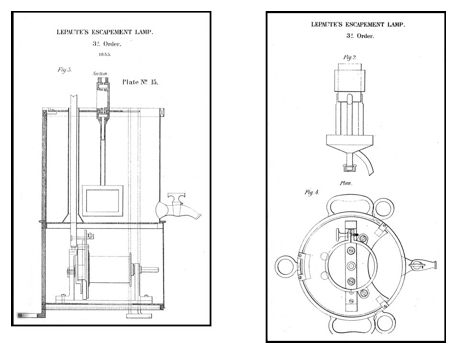

The Wagner Escapement Pump Lamp

In the 1830s, Augustin Henry-Lepaute developed the escapement lamp using metal pistons instead of the leather ones used in the original Fresnel-Arago lamps, and two groups of dual alternating pumps versus the two simple pumps in the original Fresnel-Arago lamp. It was run by clockwork through a toothed wheel known as an escapement, which allowed the pump drive mechanism to operate in only one direction. However, many technical difficulties remained in the Lepaute escapement lamp and it was not used except in trials until about 1845, when Monsieur Wagner improved its design.

In 1845, Wagner, who was an engineer working for Augustin’s brother Leonor Fresnel, improved the design of Lepaute’s escapement lamp. His design significantly strengthened the pump drive mechanism and simplified its operation. He also added a simple screw to each pump, designed to regulate the flow of the oil to the burner by reducing the opening left for the passage of oil. Wagner’s Escapement Mechanical Pump Lamps were used with the first Fresnel lenses in America.

PAGE 12

Category: Air Pressure

Type: Argand Double, Triple

Name: Pneumatic

Maker: Heap - Third District

Year of Origin: 1899

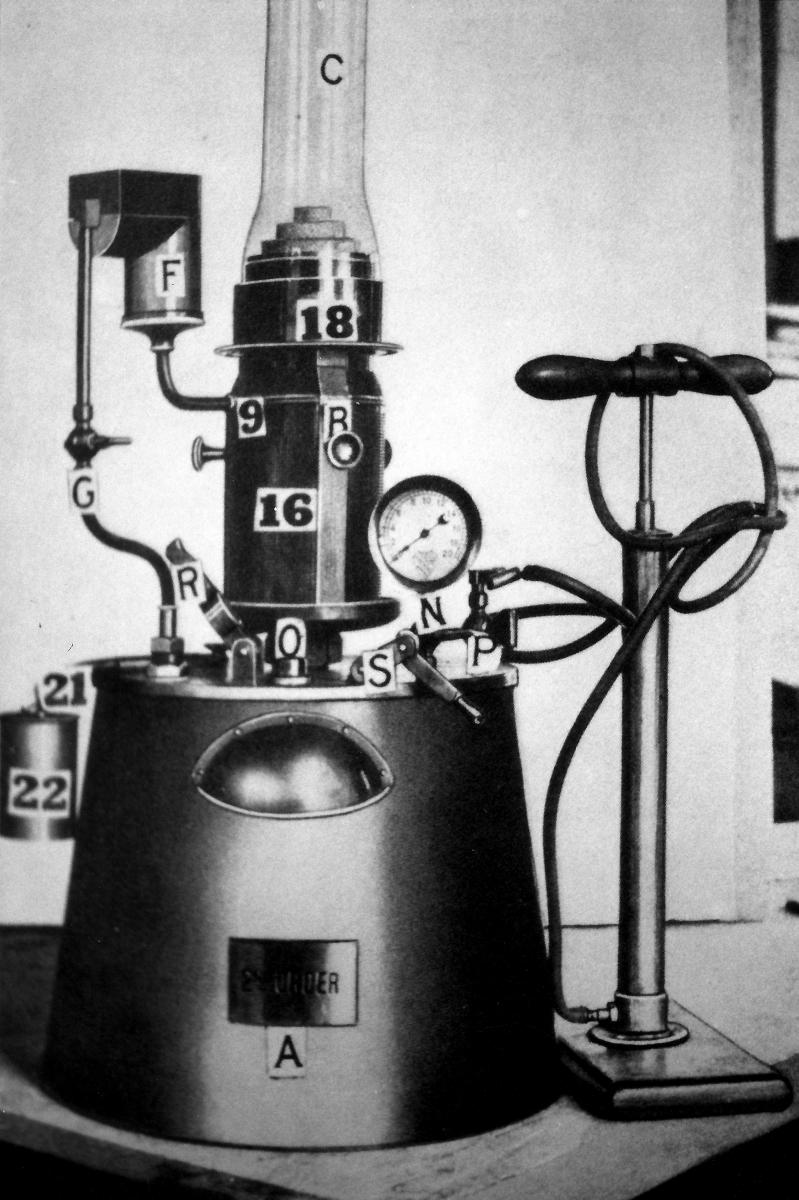

The Heap Air-Pressure-Pneumatic Lamp

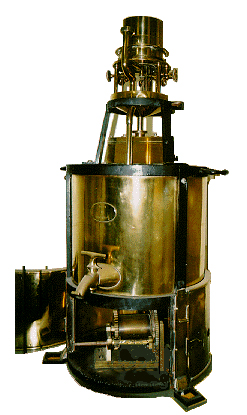

In 1899, David Heap began to study the significant maintenance problems with the hydraulic lamps then in use, and created the Air Pressure Lamp. This lamp used air pressure of 20 psi to push down on the kerosene and force it to flow to the lamp. The air pressure mechanism was very simple and very easy for the keeper to maintain. These lamps were first put into operation around 1900.

PAGE 13

Category: Incandescent Oil Vapor

Type: Mantle

Name: I.O.V.

Maker: Luchaire

Year of Origin: 1904

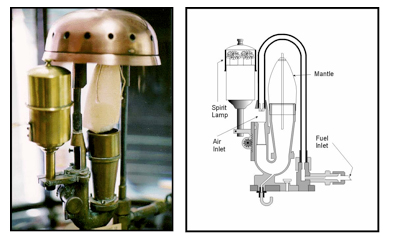

Luchaire I.O.V.

In 1901, Arthur Kitson, an American, invented an improved burner in which the oil was converted into vapor under pressure in a retort and then mixed with air in a mixing chamber to form a gas for heating a mantle made of platinum gauze. The platinum gauze quickly carbonized and within a short time Kitson abandoned it in favor of a Welsbach style incandescent mantle made of silk impregnated with zirconia. This lamp produced at least three times the light output of the Argand style lamps previously used. Another similar incandescent burner was developed by C. W. Scott, the engineer to the Commissioners of Irish Lights in 1902, and still other versions were developed by Sir Thomas Matthews, engineer to the Trinity House in England, Chance Brothers in England, Pintsch in Germany and by Luchaire in France and Diamond in Canada. The I.O.V. lamp was first used in America at the Sandy Hook lighthouse in 1904. Matthews, in England, invented the triple mantle I.O.V. lamp around 1904 and the American Lighthouse Service began testing this lamp in 1913. One of these lamps was first used in America in 1916 at the Cape Lookout lighthouse. Finally in 1921, David Hood further improved and simplified the Kitson burner.

The Luchaire I.O.V. burner came in various sizes of 35mm, 55mm, and 85mm diameter mantels.

PAGE 14

Category: Incandescent Oil Vapor

Type: Mantle

Name: I.O.V.

Maker: Chance Brothers

Year of Origin: 1904

Chance Brothers I.O.V.

In 1901, Arthur Kitson, an American, invented an improved burner in which the oil was converted into vapor under pressure in a retort and then mixed with air in a mixing chamber to form a gas for heating a mantle made of platinum gauze. The platinum gauze quickly carbonized and within a short time Kitson abandoned it in favor of a Welsbach style incandescent mantle made of silk impregnated with zirconia. This lamp produced at least three times the light output of the Argand style lamps previously used. Another similar incandescent burner was developed by C. W. Scott, the engineer to the Commissioners of Irish Lights in 1902, and still other versions were developed by Sir Thomas Matthews, engineer to the Trinity House in England, Chance Brothers in England, Pintsch in Germany and by Luchaire in France and Diamond in Canada. The I.O.V. lamp was first used in America at the Sandy Hook lighthouse in 1904. Matthews, in England, invented the triple mantle I.O.V. lamp around 1904 and the American Lighthouse Service began testing this lamp in 1913. One of these lamps was first used in America in 1916 at the Cape Lookout lighthouse. Finally in 1921, David Hood further improved and simplified the Kitson burner.

The Chance Brothers I.O.V. burner came in various sizes of 35mm, 55mm, and 85mm diameter mantels and was also available in a triple mantle version.

PAGE 15

Category: Fluid Pressure

Type: Argand Single

Name: Hydrostatic

Maker: Thilorier

Year of Origin: 1840

Thilorier’s Hydrostatic Lamp

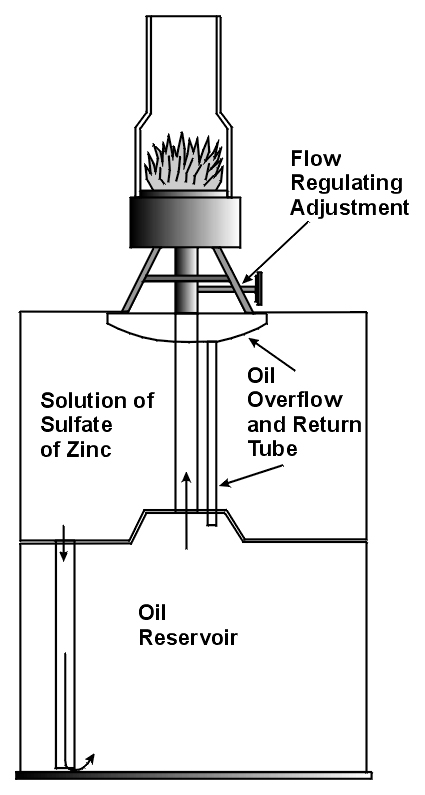

Thilorier invented an improved Hydrostatic Lamp. This lamp required the use of dissolved sulfate of zinc and a test instrument called an ‘Aerometer’ to test the density of the dissolved sulfate of zinc. Thilorier used the zinc sulfate in solution as the heavy liquid, which flowed down a tube below the oil. The oil actually floated on the zinc sulfate and was forced up a tube to the burner and on to the wicks. Any excess oil that overflowed the burner was collected and returned to the top of the oil tank by an overflow and return tube. The hydrostatic lamp was used to replace the early unreliable, clockwork driven, mechanical lamps in fixed lights where a reliable fountain or hydraulic style lamp could not be used due to its fountain and piping producing unacceptable shadows within the lens. The Scottish lighthouse service chose this lamp for use in all of their fixed lenses starting in the mid 1840s. Very few hydrostatic lamps were used in America.

The main drawback to the hydrostatic lamp was that it functioned based on the relatively minor difference in the density (specific gravity) of the zinc sulfate vs. that of the oil. If the density of the zinc sulfate solution was not exactly correct the oil would not flow at all or would flow much too quickly.

PAGE 16

Category: Gravity Feed - Fountain Lamp

Type: Argand Single

Name: Winslow Lewis

Maker: Winslow Lewis

Year of Origin: 1810

Winslow Lewis’ Lamps

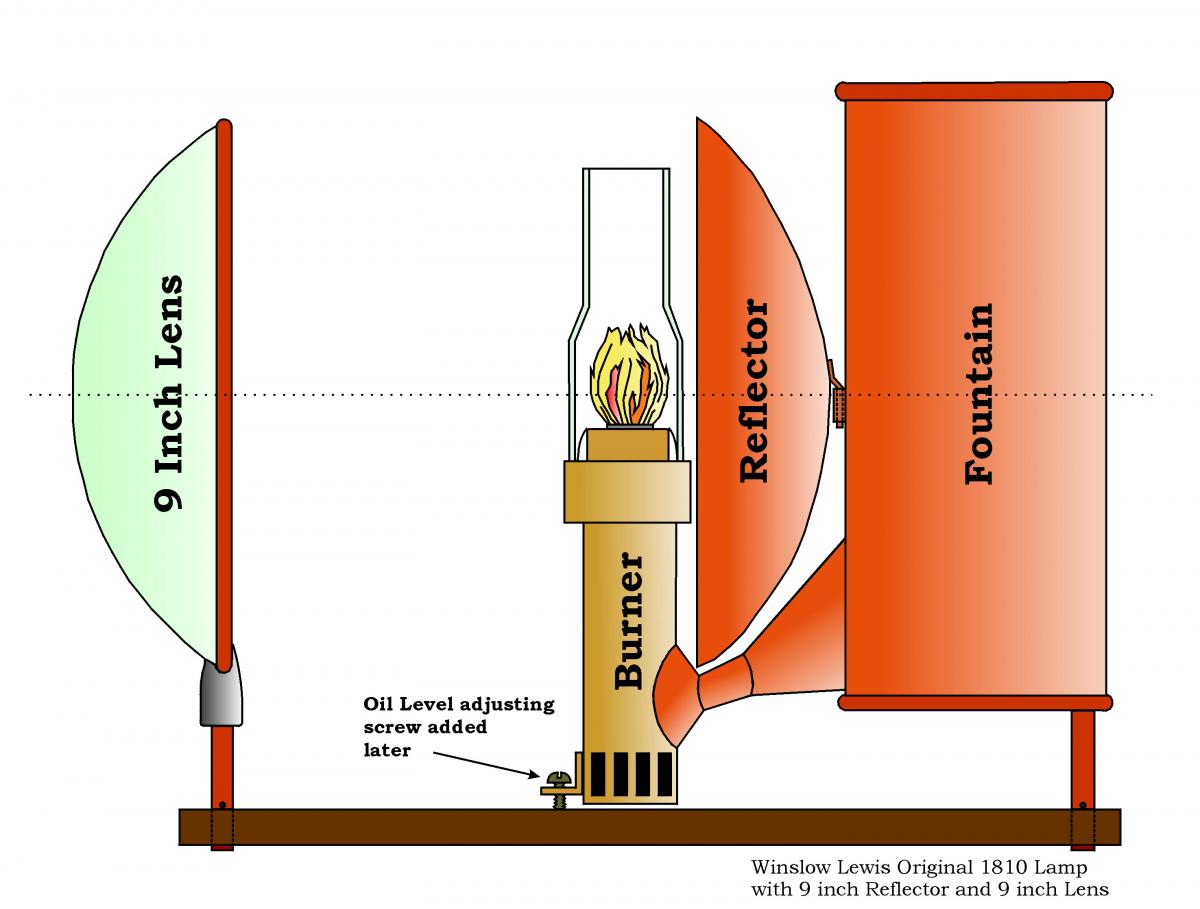

Winslow Lewis, an American ship captain, created a crude lamp design, but he succeeded in impressing the government through actual trials of the lamp’s performance and low oil consumption, which were held at the Boston lighthouse. In 1812, U.S. Government paid Lewis over $ 20,000 for his invention.

The lamp in Lewis’ design was a rough copy of an Argand style lamp with a three-quarter inch burner. The original lamp also used a short glass chimney and a simple woven-cotton lamp wick, which was poorly made, and resulted in inefficient fuel usage. Nearly all of the American lighthouses from 1812 to 1840 used the Winslow Lewis reflector and lamp design, and most continued to use the design until about 1858.

PAGE 17

Category: Gravity Feed - Fountain Lamp

Type: Argand Single

Name: Lewis-Hemmenway

Maker: Hemmenway

Year of Origin: 1834

Lewis-Hemmenway Reflector Lamps

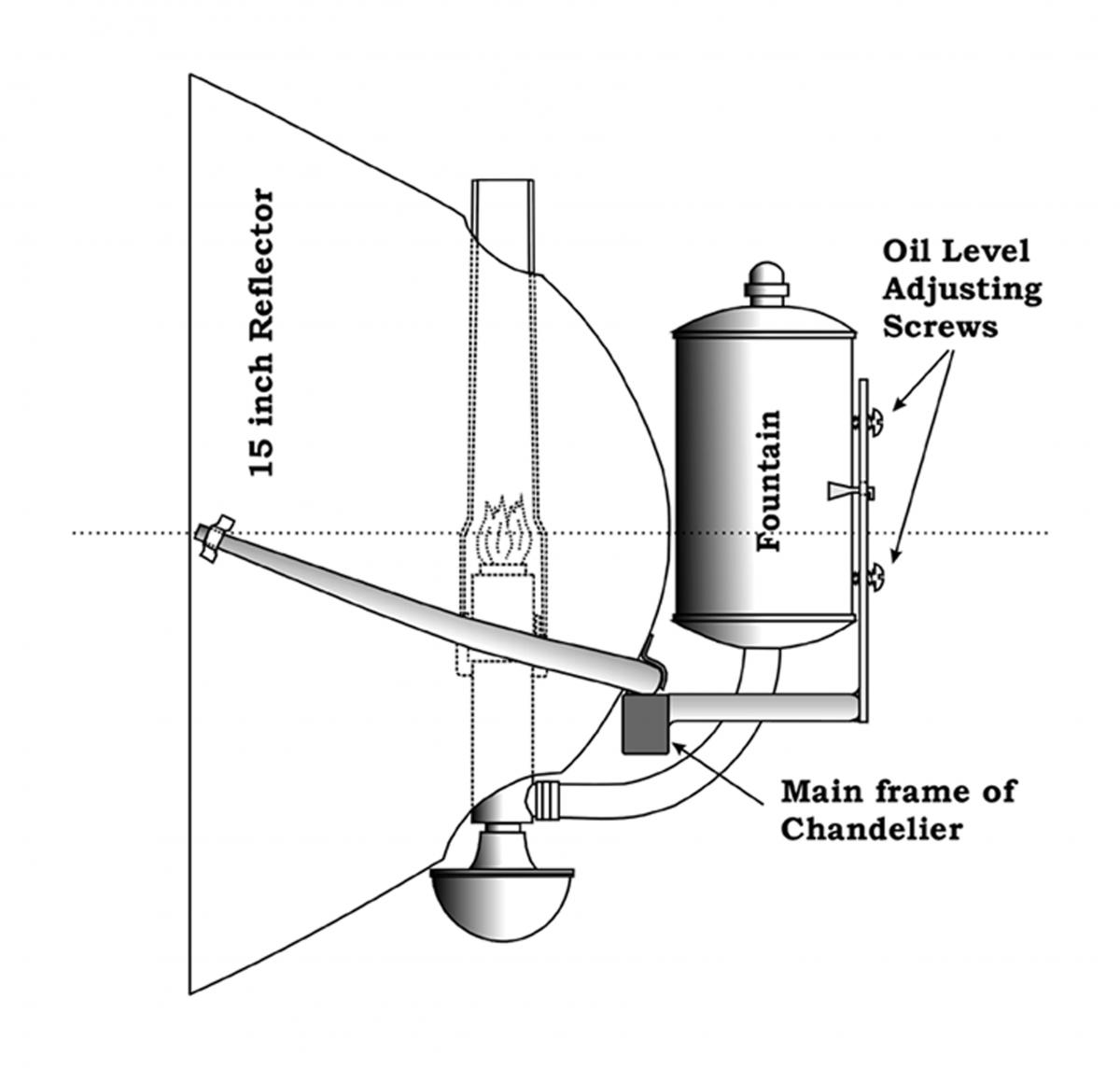

In 1834, Winslow Lewis and his supplier Benjamin Hemmenway began to produce lamps and larger reflectors. The lamp had oil level adjusting screws on the chandelier in a mounting plate behind the lamp fountain, as shown below. The lamp was a simple Argand fountain design made to keep a constant level of oil that overflowed the wick and kept the burner cool.

PAGE 18

Category: Gravity Feed - Fountain Lamp

Type: Argand Single

Name: Lighthouse Board Design

Maker: Third District

Year of Origin: 1860

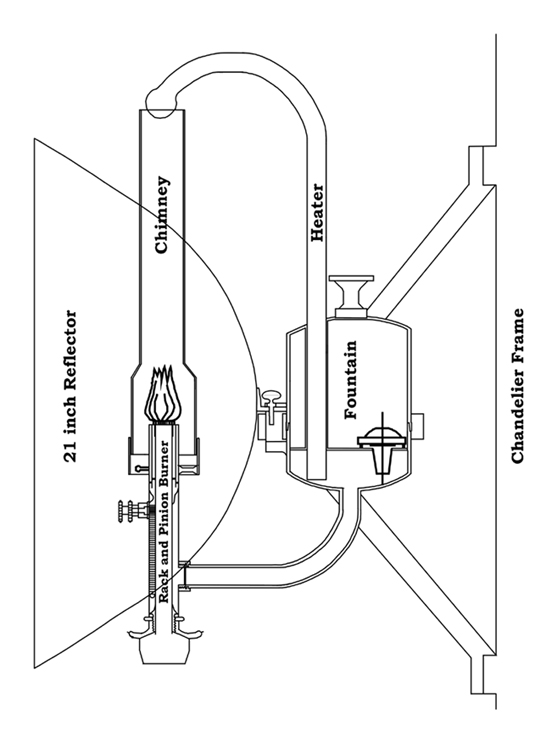

Lighthouse Board improved reflector design using a one-inch burner with a rack and pinion wick adjustment.

After the American Lighthouse Board took over in 1852, the reflector and lamp designs in use were further improved with a one-inch rack and pinion burner and rod heater, and by using still more accurate parabolic reflectors. This design was used by the Lighthouse Board beginning about 1860 for channel, range and beacon lights, and continued to be used into the early 1900s.

PAGE 19

Category: Gravity Feed - Fountain Lamp

Type: Argand Single

Name: Funck - Constant Level

Maker: Third District

Year of Origin: 1876

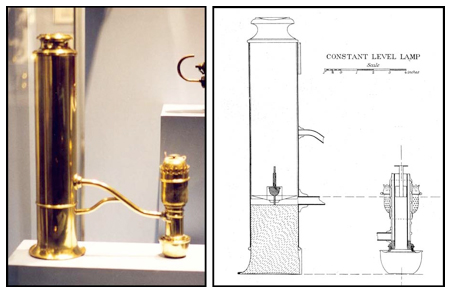

Funck’s Constant Level Fountain Lamp

The constant level lamp was used in what was known as a projector light. Projector lights were used as range lights using the constant level lamp backed by a parabolic reflector. Constant level lamps were also used with a single small Fresnel bulls-eye lens in front of the lamp as range lights.

PAGE 20

Category: Gravity Feed - Fountain Lamp

Type: Argand Triple, Quadruple

Name: Meade Hydraulic

Maker: Third District

Year of Origin: 1853

Meade’s Hydraulic Lamp

This lamp was designed by then Lieutenant George G. Meade, of the United States Corps of Topographical Engineers, and erected by him first at the Sand Key Lighthouse in Florida, and later at other locations. It should be noted that this was the same George G. Meade that would become the General leading the Union troops in the battle of Gettysburg, during the Civil War.

Meade’s lamp was intended to take the place of the French mechanical lamps of the Fresnel-Arago and Henry-Lepaute patterns, and do away with the pumps and clockwork machinery.

PAGE 21

Category: Gravity Feed - Fountain Lamp

Type: Argand Single, Double

Name: Franklin Hydraulic

Maker: Third District

Year of Origin: 1863

Franklin Hydraulic Lamp - for Fourth, Fifth, and Sixth Order Lights

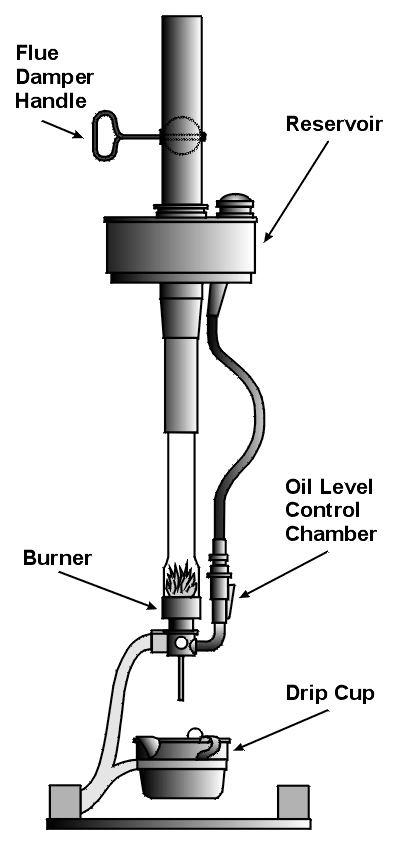

This lamp was designed by Captain William B. Franklin, United States Corps of Topographical Engineers, and Engineer Secretary of the Lighthouse Board. It consisted of four principal parts:

- An airtight reservoir, with supply tube attached, resting on the upper ring of lens.

- The burner, with reception tube and oil level control.

- A bracket, with a drip-cup fastened to the bottom ring of the lens.

- An oil level control air chamber opening into the reception tube.

PAGE 22

Category: Gravity Feed - Fountain Lamp

Type: Argand Single, Double, Triple, Quadruple

Name: Funck Hydraulic-Float

Maker: Third District

Year of Origin: 1869

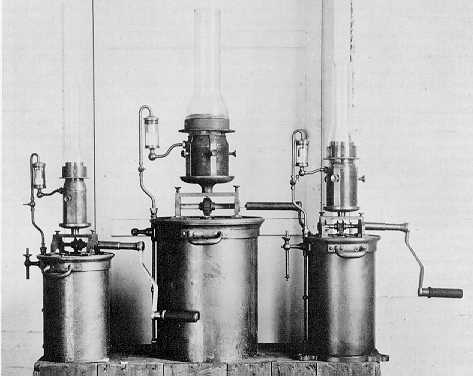

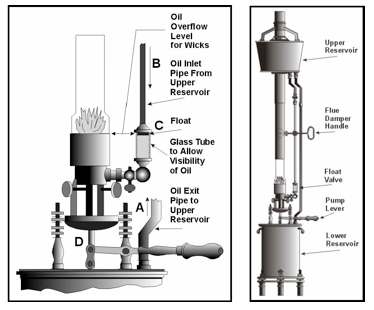

Funck’s Hydraulic-Float Lamp

The major successor to the French mechanical lamp, in America, was a lamp designed by Mr. Joseph Funck, the foreman of the American Lighthouse Service workshops at the depot on Staten Island, New York.

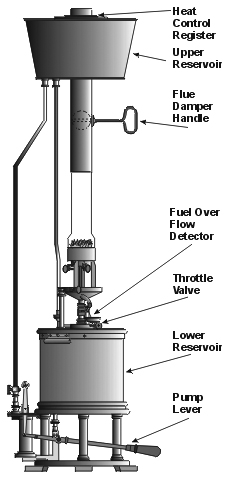

Funck’s hydraulic float lamp had a pump, operated by hand, that raised the oil from the Lower Reservoir to the Upper Reservoir through Pipe ‘A.’ The oil then flowed down from the Upper Reservoir through Pipe ‘B’ into the Float Chamber. The Float ‘C’ was donut shaped and floated upon the surface of the oil in the glass chamber. In the center of the Float ‘C’ a small needle was fixed that pointed upward into a specially shaped restriction in the oil inlet Pipe ‘B’ and when the Float Chamber was full of oil, the needle in Float ‘C’ blocked further flow of oil from Pipe ‘B’ into the Float Chamber. The oil flowed to the wick after passing through the Float Chamber. As the oil flowed into and over the wicks, some of it being burned, the oil in the Float Chamber lowered and the Float ‘C’ lowered allowing more oil to enter the chamber. Float ‘C’ was adjusted so as to rise and close the oil inlet as soon as the oil reached the proper height to just overflow the wick, thus maintaining the oil always at the same level. The overflow oil passed down through an Overflow Collector ‘D’ into the top of the Lower Reservoir.

PAGE 23

Category: Gravity Feed - Fountain Lamp

Type: Flat Wick

Name: Funck 8-Day

Maker: Third District

Year of Origin: 1885

Funck’s 8-Day Lamp

In the early 1880s, there was a great need for lanterns that could be used as beacon lights on small piers and as post lamps, functioning as the warning lights for obstacles on the major inland rivers. The problem with the lamps, in use at the time, was their need for constant attention. In 1885, Joseph Funck developed the idea of adding a large circular tank for oil around the top of the lamp, giving it the capacity to operate for up to 8 days without attention. This design worked quite well, but the lamp itself was the old-fashioned flat wick variety and the lens was made of pressed glass of rather poor quality. The lamp was also susceptible to being blown out by strong winds.

PAGE 24

Category: Gravity Feed - Fountain Lamp

Type: Argand Single

Name: Heap 5 and 8-Day Lens Lantern

Maker: Third District

Year of Origin: 1889

Heap’s 5 and 8-Day Lamps

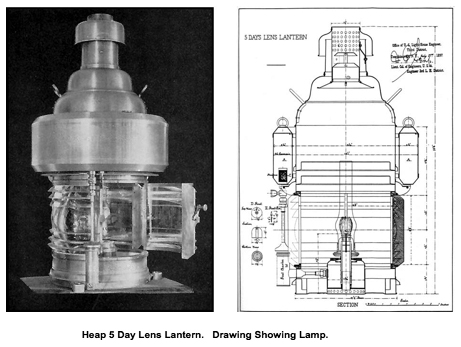

In 1889, David Heap developed a further improved design for the American 8-day lantern and invented a new 5-day lantern. He described his thoughts in a report to the Lighthouse Board as follows:

“The eight-day tubular lens-lanterns having proved quite successful so far as maintaining a light without attention during that length of time, I believed that it would be advisable to apply the same principle to a lantern with cut-glass prisms, using a lamp with a circular burner and a chimney, and thus obtain a much more powerful light.”

PAGE 25

Category: Spring Piston

Type: Argand Single

Name: Moderator

Maker: Franchot

Year of Origin: 1836

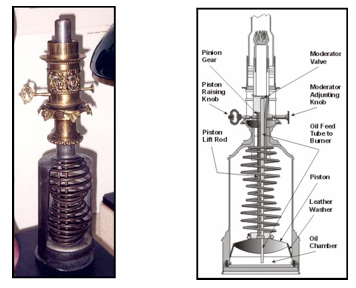

Franchot’s spring operated Moderator Lamp

In 1836, Monsieur Franchot invented the Moderator lamp where a spiral spring operated piston made oil flow to the wicks through a constricted valve known as the moderator. These lamps were used in most fixed lenses in France, and in America when Fresnel lenses were first installed during the 1850s. However, they were not used in American lighthouses after about 1865.

The machinery placed in the reservoir of the lamp was formed by a spiral spring attached to a lightweight piston. The piston was made from a sheet-iron disk, fitted with a leather washer, and connected to a tube, which fed the burner. A square rod with gear teeth was connected to the piston, which served to raise the piston and compress the spring. The lamp was wound by turning a key fixed at the top of the burner, which operated a pinion gear meshed with the teeth of the square rod. It was necessary to windup the lamp before it was first lit each night, and it was necessary to rewind it at the end of about four hours’ combustion. The piston, under pressure from the spring, pushed down on the oil, which forced it up the oil-feed tube to the moderator valve where it entered the base of the burner and fed the wick.

Franchot’s moderator lamp was difficult to maintain because its spring drive was prone to getting stuck, its winding mechanism was easily jammed, and the moderator valve was difficult to properly maintain and provided only a very course fuel flow control.

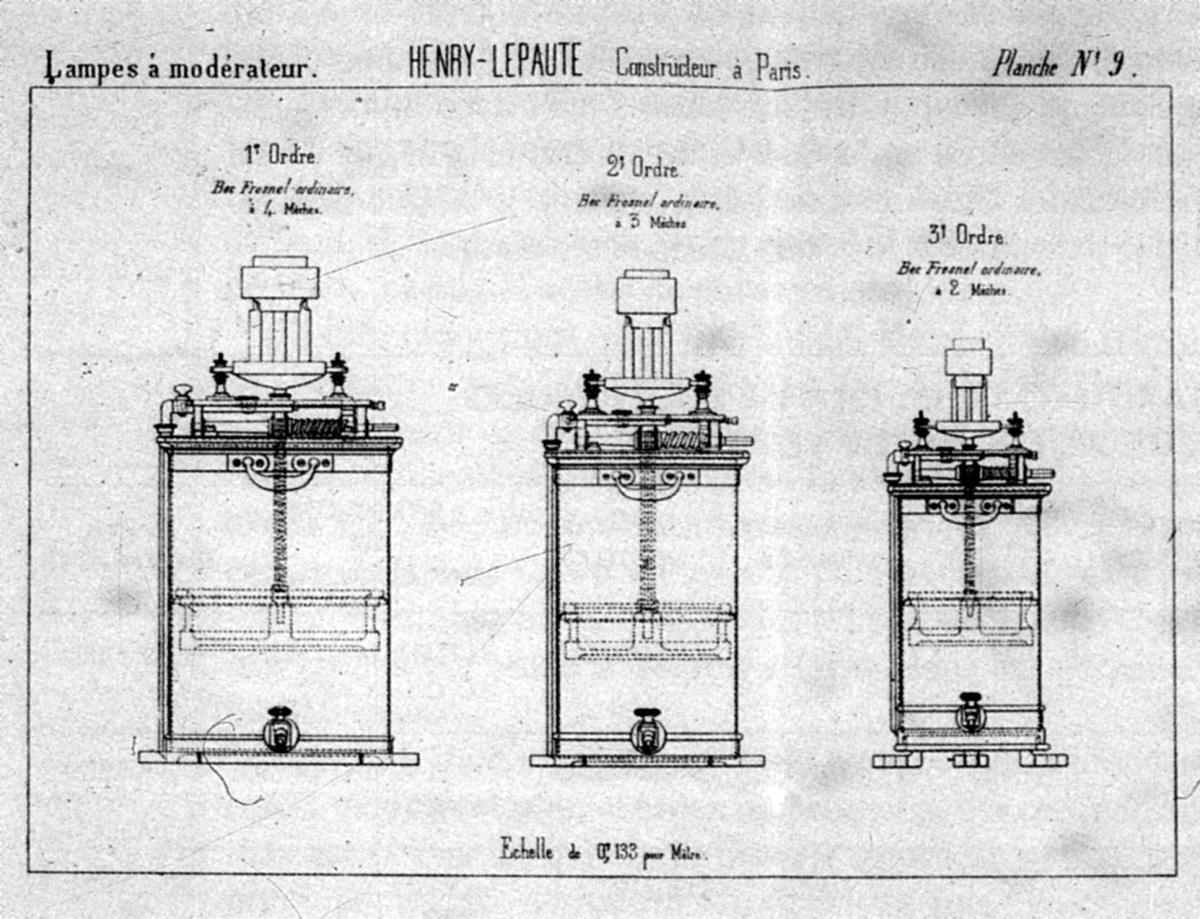

PAGE 26

Category: Weighted Piston

Type: Argand Double, Triple, and Quadruple

Name: Moderator

Maker: Henry-Lepaute

Year of Origin: 1845

Lepaute’s Moderator Lamp

Augustin Henry-Lepaute began to redesign the moderator lamp in the early 1840s. He replaced the drive spring with a much heavier piston and replaced the wind up gearing with a chain drive that allowed the heavy piston to be easily raised with a crank. The moderator valve was replaced with an easily adjusted needle valve that moved automatically as the piston was lowered. These changes significantly improved the reliability of Lepaute’s moderator lamp. However, the piston was still prone to become stuck and its leather seal wore out rather quickly. Most of the world’s lighthouses converted to this lamp starting ca. 1860.

In this lamp the heavy piston pushed down on the oil only through its own weight and forced the oil up a tube on the side of the lamp body. The oil flowed up the tube into a chamber with a tiny hole located at the end toward the center of the lamp where the moderator needle was positioned. The moderator needle allowed a small and highly controlled flow of oil to pass into the burner at a steady rate.

PAGE 27

Category: Weighted Piston with Float

Type: Argand Triple, Quadruple, and Quintuple

Name: Funck Moderator-Float

Maker: Third District

Year of Origin: 1883

Funck’s Moderator Float Lamps

Early in 1874, Joseph Funck, the foreman of the Lamp Shop at the Tompkinsville New York Depot, was assigned to begin analyzing any changes necessary in the design of burners for the use of kerosene. Joseph Funck was given a patent for his version of the kerosene burner for lighthouses on November 28, 1876. Captain Doty was continuing to further describe his design and on March 28, 1877, he asked for a second reissue of his patent to describe some additional features of his original design that he felt Funck was infringing upon, and began a lawsuit against the Lighthouse Board and Funck. On December 5, 1878 there was a final decision of the Supreme Court of the District of Columbia. In this decision Funck and the Government won every point and Funck’s multi-wick design was declared to be free of any patent infringement related to H. H. Doty or anyone else. The Lighthouse Board now had the right to deploy Funck’s multi-wick kerosene burners throughout the system. Funck’s Moderator design kerosene lamps were developed in 1883.

PAGE 28

Category: Special

Type: Candle

Name: River Post Candle Lantern

Maker: Third District and Post & Co.

Year of Origin: 1885

River Post Candle Lantern

In approximately the year 1885, the Lighthouse Service decided to place very inexpensive river post lanterns on wooden frames along the major navigable rivers. These lanterns used candles as the illumination method and are not true lamps as are the previous categories.

PAGE 29

Category: Compressed Gas

Type: Acetylene

Name: Flasher Regulator

Maker: AGA

Year of Origin: 1907

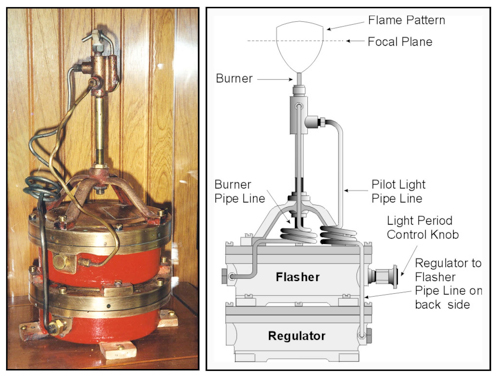

Acetylene Flasher-Regulator

The earliest use of acetylene gas in buoys occurred in 1896. The acetylene burner and flasher-regulator lamp were continuously improved and the Lighthouse Service began to use the AGA flasher-regulator in the year 1913.