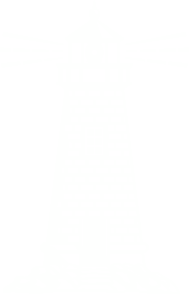

The ingenuity of man is truly amazing and this can easily be seen in the odd collection of techniques used for the illumination of lighthouses across the centuries. Lighthouse illumination began with simple wood fires and progressed through generations of other methods. Even the oil lamp began in simplicity and evolved into a machine with multiple wicks, clockwork oil pumps, specialized chimneys, hydraulic, pneumatic, and other variants. This story will take you through the history of illumination methods in lighthouses.

Braziers

Coal and Wood Fires

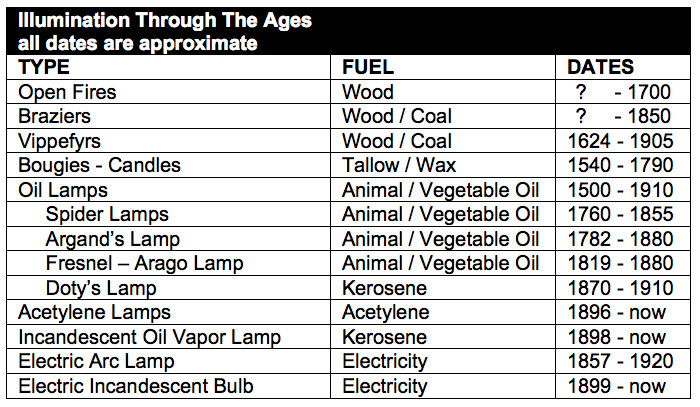

The early mariner’s warning lights consisted chiefly of open fires and later of fire beacons maintained on a grate or in an iron basket known as a brazier and shown from an elevated location or platform near the coast. They were often unreliable because of the variability between burning well, with lots of flame and therefore light, or burning poorly with little flame or much smoke obscuring the light. These beacons were maintained both by public and private enterprises. Patents were granted to certain individuals for the upkeep of beacons in England and Scotland. While in other countries, the governments accepted the total responsibility for building and maintaining the warning lights.

The first English lighthouse to use mined coal was Dungeness in 1616, and its coal-fired brazier consumed as many as 400 tons of coal per year. The quality of the light from brazier coal fires varied considerably with weather conditions. When a strong wind blew off the land toward the sea, the light on the seaside became quite bright, but when the wind came from off the water the side of the fire facing the sea would be quite dark, while the land side of the fire was bright, yet useless. This was a great problem, because it was precisely when the wind was blowing toward shore that the most brilliant light was needed, and the most danger to shipping was present.

At first these fires were burnt in the open, but later they were enclosed by a lantern provided with a ventilating flue in an attempt to carry away the smoke, which would form around the fire and frequently obscure the light. The lanterns were not always a success as the glazing became blackened, and in a number of cases they were removed. One of the earliest known coal-fire towers to be fitted with a lantern is to be found on the island of St. Agnes in the Isles of Scilly in England. It was built in 1680, and the brazier, in which the fire was burnt, is still in existence.

The Isle of May, in Scotland, was the location of an old lighthouse established in the year 1636. The original lighthouse consisted of a stone tower with a large brazier for the burning of coal at its’ top. The coal was set alight each night and burned an average of a little over one ton of coal per night. The coal fire was exhibited every night from the lighthouse’s opening in 1636 until February 4, 1816, when it was replaced by a new lighthouse using reflectors, each with an Argand style oil lamp. A primitive block and tackle was used to raise the coal to the brazier on the top of the tower by the three men who were assigned to the stoking of the fire. The old coal fires survived in England until 1822, and there were examples of such lights in service in the Baltic region until 1850.

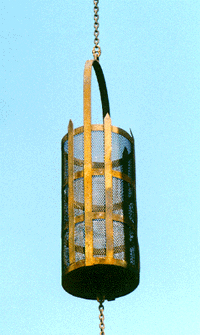

(Photo from the Egbert Koch collection) Brazier Fire Basket at the Skagen ‘Hvide Fyr’ Light. (ca. 1700)

Vippefyrs

In Denmark, Jens Pedersen Groves designed the Vippefyr in 1624, which utilized the lever principle to raise a fire into the air. He drove one end of a large square beam in the ground strengthened by several additional diagonal supports. Pivoted from the main beam was a balanced cross member, or lever. One end of the lever was attached by a chain to a large fire basket, while the other end was weighted to facilitate raising the fire basket some 14 to 30 feet into the air. The long end of the lever, with the fire basket, was usually covered with metal sheathing as a protection against fire. The fire basket could be lowered when the keepers needed to fill it with coal or wood or to stoke the fire. It was then raised again to show the signal. One of the last Vippefyrs to be used was as a small local light on the island of Gothland, in Denmark, in 1905.

In England a similar device known as the Swape was used. The coal or wood fire was made in a metal basket, which could be easily tended on the ground and then elevated by means of the Swape, or fire lever. The great English Civil Engineer, John Smeaton visited Spurn Point in 1767 and decided to use a Swape there. He designed an improved version of the Swape with a small umbrella to protect the control rope from falling cinders.

(Photo from the Egbert Koch collection) The Vippefyr at Skagen Denmark. (ca. 1624)

(Photo from the Egbert Koch collection) The Vippefyr’s Fire Basket.

Bougies and Candles

The first use of candles consisted of a simple lantern shown at a window by a hermit or a monk. It was only when the enclosed lantern room was developed that the use of candles was made possible for use in lighthouses. The light from individual candles was rather feeble however, when a number of candles were placed in a candelabrum, and protected from the wind by the lantern windows, the light was a significant improvement over that from the coal fires. Candles were used in many lighthouses in Europe in the 1500s and were first used in England at the North Shields lighthouse in 1540. In France the name for candles was Bougies, which were made from tallow and used in their earliest lighthouses. The first lighthouse illumination in America came also from tallow candles, which were used for several years in the first Boston lighthouse and in most other early 18th century American lights. The keepers usually made the candles on site, because commercially produced candles were virtually nonexistent. Wax candles were used, but were very expensive; tallow candles were cheaper, but smoky and bad smelling.

In the original Winstanley Eddystone lighthouse, 60 one-pound candles were used when it was first lit in 1698. In Smeaton’s Eddystone lighthouse in 1759, the first light exhibited was from 24 candles, which produced a rather feeble light, although, it is said that the light could be seen by telescope from Plymouth Hoe, 12 miles away. The candles Smeaton used at Eddystone weighted 2/5 of a pound each and the 24 candles had to be replaced about once every 3 hours.

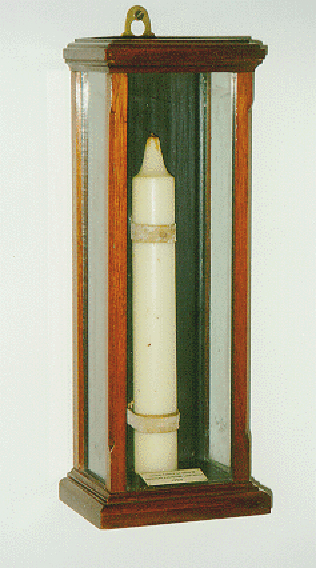

A replica of the candelabra originally installed in the Eddystone lighthouse. (1759)

An actual candle from the Eddystone lighthouse. (1759)

Oil Lamps Overview

The Cresset was one of the earliest forms of oil lamp used in a lighthouse. It consisted of a bowl hollowed out of stone, which was filled with fish oil, with one or more small rope wicks. As the years passed, several other types of oil lamps began to be used. The lamps, were usually made by local artisans, and began to be used as early as 1500. At this time, there were no standard types of lamps in use; however, most lamps had solid-rope wicks made of loosely braided cotton and a rather small common oil reservoir that fed one or more wicks. These lamps initially burned fish oil, seal oil, and later whale oil. They used no chimneys or reflectors, and produced a very poor light with much smoke and acrid fumes. Small tin lamps were tried, but failed due to their lack of a sufficient oil supply and poor flame qualities. The solid wicks had very poor combustion of the oil on the wick, producing large quantities of smoke. Later improvements were made by flattening the wicks to allow the ambient air to better reach both sides. While this produced a better flame, some smoke and soot was still produced, and portions of the oil remained unconsumed by the flame.

Spider Lamps

By the 1760s, a form of Spider Lamp known as the Pan Lamp replaced the other early oil lamps in some lighthouses. The Sandy Hook light, in New Jersey, built in 1764, is reported to have used two Pan Lamps with a total of 48 oil blazes, hung from the lantern room ceiling by chains. Pan Lamps came in several forms. There were circular and rectangular pans, and a donut shaped Pan Lamp was used in the early lightships. Pan Lamps with a circular form were also known as Compass Lamps.

The Pan Lamp solved the problem of a limited oil supply and could operate for twelve or more hours on one fill of oil. The Pan Lamp had multiple rope wicks. The number of wicks varied from two too as many as twenty-four, with eight to ten wicks being very common. The Pan Lamp produced more light than the other early oil lamps because individual large diameter wicks were placed nearly side by side across the surface of the metal pan, and the flames could all be seen at the same time. Its main drawbacks were its relatively low light output, its massive consumption of oil, and the smoke and fumes produced within the lantern room, which at times became almost intolerable.

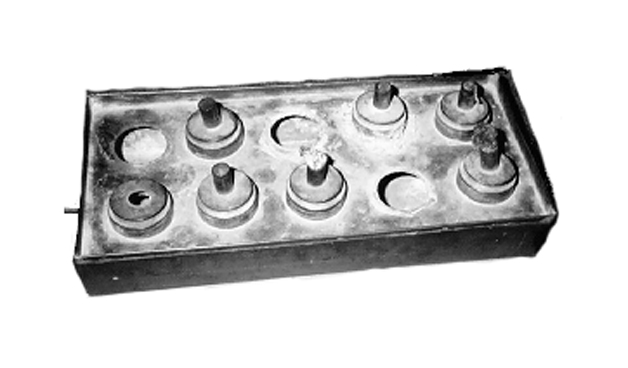

A typical Pan Lamp with ten ‘blazes.’ (ca.1760)

Pan Lamps were used for a very long time. The early light lists show a Compass Lamp with 8 wicks still in use at the Vermilion beacon light, in Ohio, in 1849. Compass Pan Lamps were the only style of lamp in use on American lightships until the mid 1850s.

The Bucket Lamp, another form of Spider Lamp, had been available for many years and began to be used in lighthouses in the latter part of the 1700s, mainly in the smaller lighthouses, beacon, and pier-head lights. The Bucket Lamp was made of sheet metal and was cylindrical in shape, with two or four spouts protruding from its sides. Each spout carried a large diameter rope wick that extended down inside the body of the lamp into the oil. Below each spout was a similarly shaped drip catcher. The Bucket Lamp held up to an eight-quart oil supply and could operate for twelve or more hours on one fill of oil. Its main drawbacks were still the very poor light produced, the smoke and fumes, and the problem that some of the flames were hidden from view behind the bucket, when it was viewed from specific directions. The Cape Henry light used this style lamp in 1792 and burned fish oil probably from Herring. The use of Bucket Lamps lasted a long time and four were recorded as being in use in 1845, at the Cunningham Creek Beacon light in Ohio.

A typical Bucket Lamp with two wicks. (ca. 1780)

Fountain Lamps

Fountain lamps use a closed container of fuel with a small valve at its lower end. The valve is set at a height slightly below the top of the wick in the lamp burner. As fuel is burned, the valve in the fountain opens slightly to admit additional oil into the tube going to the burner. The fountain lamp maintains the fuel at a constant level at the burner. Fountain lamps function through capillary attraction and do not overflow the wicks.

Argand’s Lamp

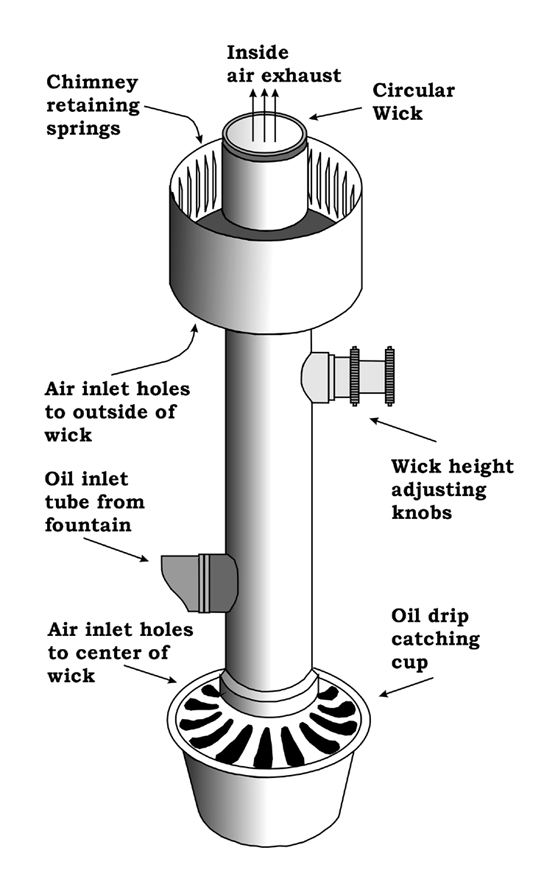

In 1782, François-Pierre Ami Argand (1750-1803), a Swiss born physicist living in France, invented the double draft burner, which became known as the Argand oil lamp. Argand’s design used two thin metal tubes with one set inside the other. The wick was placed between these tubes and was thus formed into a long hollow cylinder. Air was allowed to enter the center of the wick through holes placed in the oil drip-cup attached to the bottom of the wick tubes. Air was also allowed to enter around the outside of the outer wick tube, through holes in the bottom of the chimney holder. Argand’s design provided much more oxygen to the flame, more efficient fuel combustion, and a much brighter light. Argand also invented the use of a chimney, which helped to provide additional airflow over the wick and protected the flame from outside air currents, which could make it flicker.

(Drawing by Author from a Lighthouse Board Drawing) A typical Argand Lamp Burner. (1782)

In 1787, another Frenchman, Monsieur Lange, invented the constricted chimney, which Argand quickly added to his design. The constricted chimney forced the outside air closer to the flame. This action further improved the combustion of the fuel, giving a still brighter flame, which was measured at about 7 candlepower.

Robert Stevenson’s Lamp

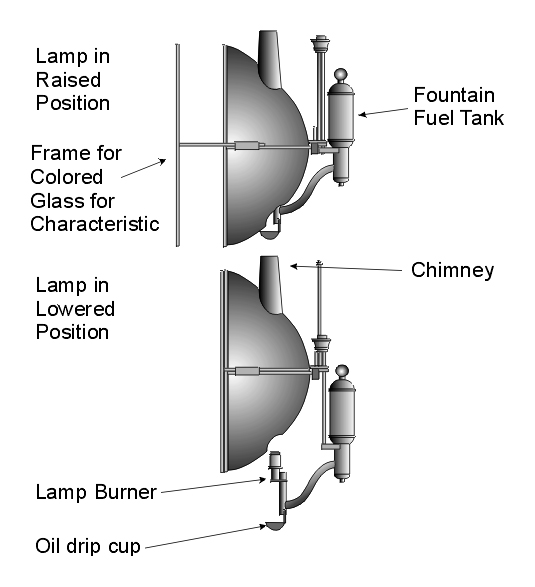

From 1803 to 1810, Robert Stevenson worked to improve the design of Scotland’s copper parabolic reflectors and lamps. He chose an improved Argand lamp with a fountain fuel tank set in a true parabolic reflector with a heavy cladding of silver. The fountain fuel tank held 24 ounces of fuel. By 1809, he had succeeded in developing a design where the lamp was able to be released from the focus of the reflector by turning a locking ring, that let the lamp assembly slide down, allowing easy wick replacement or trimming, and allowing easy polishing of the inside of the reflector. When the work was completed, the keeper raised the lamp back into its preset position, in the reflector’s focus, and locked it with the ring. Stevenson’s new lamps were first installed in the Bell Rock lighthouse in 1811.

(Drawing by Author from Drawing in Lighthouse Illumination 1859) Robert Stevenson’s Retractable Lamp with Reflector. (1811)

Winslow Lewis’ Lamps

Winslow Lewis, an American ship captain, created a crude lamp design, but he succeeded in impressing the government through actual trials of the lamp’s performance and low oil consumption, which were held at the Boston lighthouse. In 1812, U.S. Government paid Lewis over $ 20,000 for his invention.

(Drawing by Author from patent drawing) Winslow Lewis Lamp Patent 2901-X. (1818)

The lamp in Lewis’ design was a rough copy of an Argand style lamp with a three-quarter inch burner. The original lamp also used a short glass chimney and a simple woven-cotton lamp wick, which was poorly made, and resulted in inefficient fuel usage. Nearly all of the American lighthouses from 1812 to 1840 used the Winslow Lewis reflector and lamp design, and most continued to use the design until about 1858.

(Drawing by Author from Patent Drawing) Winslow Lewis / Benjamin Hemmenway Lamp. (1844)

Oil and Kerosene Lamps for use in Fresnel Lenses

A number of styles of lamps were used within the Fresnel lenses. They varied both by the operating principals of their construction and by the order, or size, of the Fresnel lens in which they were placed. The main styles of lamps were as follows:

Capillary Lamps

Capillary lamps are based on the principle of capillary attraction where the fuel is raised to the flame by the wick itself. In these lamps the fuel is stored below the burner and the fibers of the wick soak up the fuel and raise it from the fuel reservoir to the top of the wick through capillary action within the fibers. These lamps were used in the fourth-order and smaller lenses.

Funck’s Improved Fourth-Order Lamp (1888)

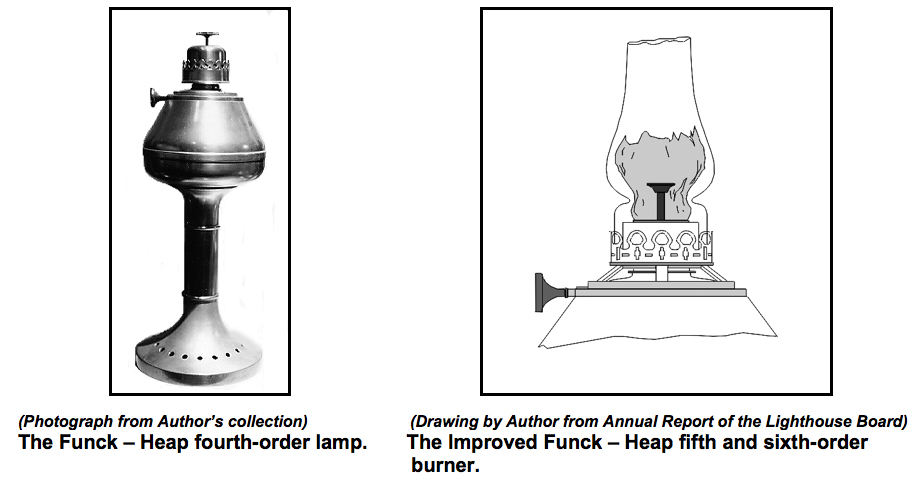

In 1888, Joseph Funck was able to dramatically improve the lamps used in the fourth-order lenses in America. Funck redesigned the old fourth-order lamp and produced the ‘improved-fourth-order lamp,’ which had a new flame spreader and a number of airflow adjustments.

The Funck-Heap Lamp (1892)

In the smaller lighthouses a lamp called the Funck-Heap lamp was introduced in 1892. It was a standard Argand lamp with a single one and one-eighth-inch wick. There was a flame-spreading button in the center of the flame that got red-hot and helped to keep the flame a constant size and shape. The feeding of the wick was accomplished by a screw thread on the wick carrying tube. The Funck-Heap lamp became the standard lamp used in all fourth-order lenses in the American Lighthouse Service and was refitted into all of the lighthouses using a fourth-order lens as quickly as it could be manufactured. The same design with slight variations in the flame spreader and chimney was developed for the fifth and sixth-order lamps.

Funck’s Constant Level Fountain Lamp (1876)

The constant level lamp was used in what was known as a projector light. Projector lights were used as range lights using the constant level lamp backed by a parabolic reflector. Constant level lamps were also used with a single small Fresnel bulls-eye lens in front of the lamp as range lights.

American Constant Level Lamp.

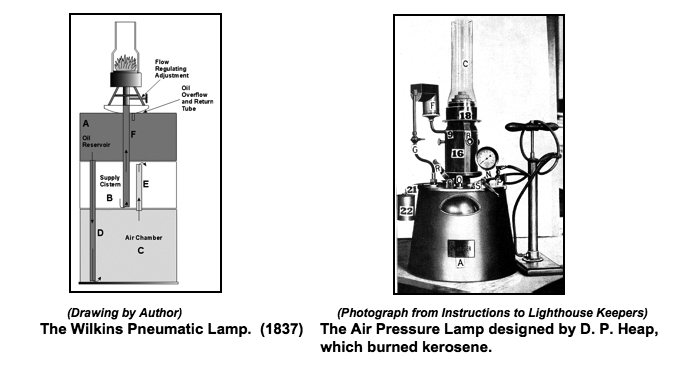

Mechanical Overflow Lamps

Fresnel-Arago Clockwork-Concentric-Wick Lamps (1819)

Augustin Fresnel and François Arago used the ideas of Count Rumford and the Guyton de Morveau to design new Argand style lamps, and made a series of trials of lamps with various numbers of concentric wicks, in late 1819. It was found that a standard Argand lamp, even with multiple concentric wicks, would not perform as required, because the multiple wicks caused such great heat that the burner would melt and the wicks would quickly char. After many trials it was found that the Argand style lamp invented by Monsieur Bertrand Carcel in 1800 could be used with multiple concentric wicks.

The Carcel lamp had a double-piston-mechanical pump operated by clockwork that forced excess oil through a tube to the wick, overflowing the wick and cooling the entire burner. By December 1819, Fresnel and Arago had created a multiple-concentric-wick lamp using the Carcel cooling principal and the first triple-wick burner was operational in their laboratory. Within a few months, they also developed a quadruple-wick burner and proposed its use within the first, first-order lens that was manufactured.

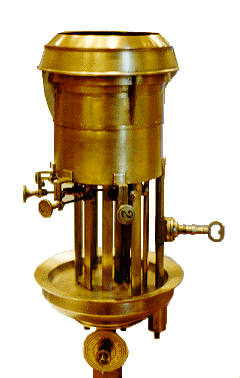

An early Fresnel-Arago Lamp with a Carcel pump clockwork shown in the base. (1823)

French Two Wick Lamp. (1840)

The Lepaute Escapement Lamp (ca.1830)

In the 1830s, Augustin Henry-Lepaute developed the escapement lamp using metal pistons instead of the leather ones used in the original Fresnel-Arago lamps, and two groups of dual alternating pumps versus the two simple pumps in the original Fresnel-Arago lamp. It was run by clockwork through a toothed wheel known as an escapement, which allowed the pump drive mechanism to operate in only one direction. However, many technical difficulties remained in the Lepaute escapement lamp and it was not used except in trials until about 1845, when Monsieur Wagner improved its design.

The Wagner Pump Lamp (1845)

In 1845, Wagner, who was an engineer working for Augustin’s brother Leonor Fresnel, improved the design of Lepaute’s escapement lamp. His design significantly strengthened the pump drive mechanism and simplified its operation. He also added a simple screw to each pump, designed to regulate the flow of the oil to the burner by reducing the opening left for the passage of oil.

Franchot’s spring operated Moderator Lamp (1836)

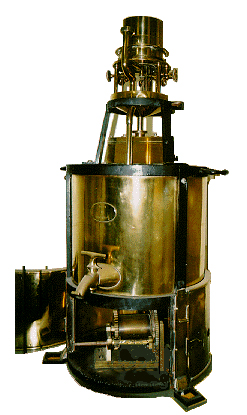

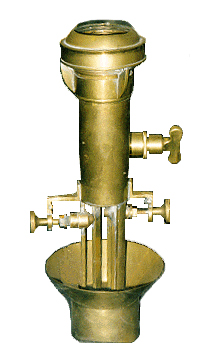

In 1836, Monsieur Franchot invented the Moderator lamp where a spiral spring operated piston made oil flow to the wicks through a constricted valve known as the moderator. These lamps were used in most fixed lenses in France, and in America when Fresnel lenses were first installed during the 1850s. However, they were not used in American lighthouses after about 1865.

The machinery placed in the reservoir of the lamp was formed by a spiral spring attached to a lightweight piston. The piston was made from a sheet-iron disk, fitted with a leather washer, and connected to a tube, which fed the burner. A square rod with gear teeth was connected to the piston, which served to raise the piston and compress the spring. The lamp was wound by turning a key fixed at the top of the burner, which operated a pinion gear meshed with the teeth of the square rod. It was necessary to windup the lamp before it was first lit each night, and it was necessary to rewind it at the end of about four hours’ combustion. The piston, under pressure from the spring, pushed down on the oil, which forced it up the oil-feed tube to the moderator valve where it entered the base of the burner and fed the wick.

Franchot’s moderator lamp was difficult to maintain because its spring drive was prone to getting stuck, its winding mechanism was easily jammed, and the moderator valve was difficult to properly maintain and provided only a very course fuel flow control.

Lepaute’s Moderator Lamp (ca. 1845)

Augustin Henry-Lepaute began to redesign the moderator lamp in the early 1840s. He replaced the drive spring with a much heavier piston and replaced the wind up gearing with a chain drive that allowed the heavy piston to be easily raised with a crank. The moderator valve was replaced with an easily adjusted needle valve that moved automatically as the piston was lowered. These changes significantly improved the reliability of Lepaute’s moderator lamp. However, the piston was still prone to become stuck and its leather seal wore out rather quickly. Most of the world’s lighthouses converted to this lamp starting ca. 1860.

In this lamp the heavy piston pushed down on the oil only through its own weight and forced the oil up a tube on the side of the lamp body. The oil flowed up the tube into a chamber with a tiny hole located at the end toward the center of the lamp where the moderator needle was positioned. The moderator needle allowed a small and highly controlled flow of oil to pass into the burner at a steady rate.

Pneumatic Lamps

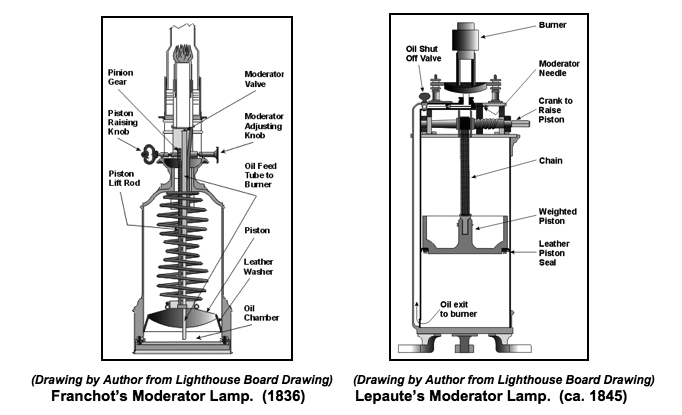

Pneumatic lamps operate through the use of air pressure to maintain a flow of oil or kerosene from the fuel reservoir below the burner up to the wicks.

The Wilkins Pneumatic Lamp (1837)

This lamp is composed of a Reservoir ‘A’, which is filled with oil, a Supply Cistern ‘B’ filled with oil, and an Air Chamber ‘C’. There is a Tube ‘D,’ which passes from the bottom of the Reservoir ‘A’ to the Air Chamber ‘C’ through which the oil passes into the Air Chamber ‘C.’ A Tube ‘E’ from the top of the Air Chamber ‘C’ passes up into the Supply Cistern ‘B.’ The main Tube ‘F’ leading to the burner passes from the center of the Supply Cistern ‘B’ up through the Reservoir ‘A’ to the burner. The pressure of the oil from the Reservoir ‘A’ into the Air Chamber ‘C’ will force the air into the Supply Cistern ‘B’, and cause the oil to flow to the burner, so long as there is any oil in the Reservoir ‘A.’

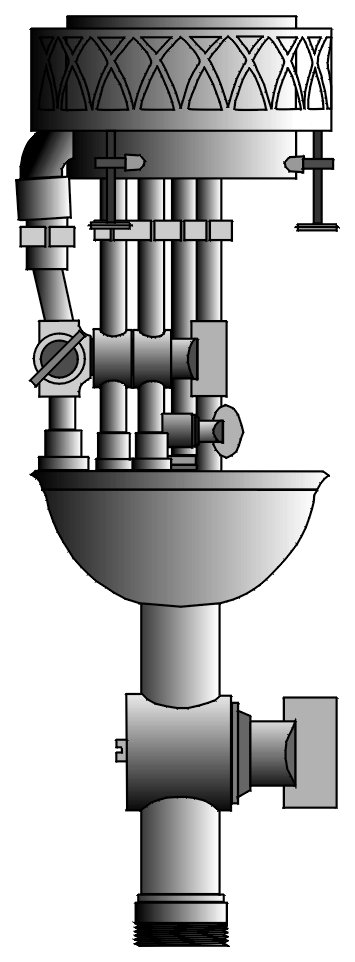

The Heap Air-Pressure-Pneumatic Lamp (1899)

In 1899, David Heap began to study the significant maintenance problems with the hydraulic lamps then in use, and created the Air Pressure Lamp. This lamp used air pressure of 20 psi to push down on the kerosene and force it to flow to the lamp. The air pressure mechanism was very simple and very easy for the keeper to maintain. These lamps were first put into operation around 1900.

Hydrostatic Lamps

The Hydrostatic lamp was the invention of Peter Kier in 1787. It used the weight of a liquid slightly heavier than the oil, which would flow below the oil and force it up a tube to the wicks. It was not used in lighthouses until it was significantly improved through the efforts of the French chemist Thilorier many years later.

Thilorier’s Hydrostatic Lamp (ca. 1840)

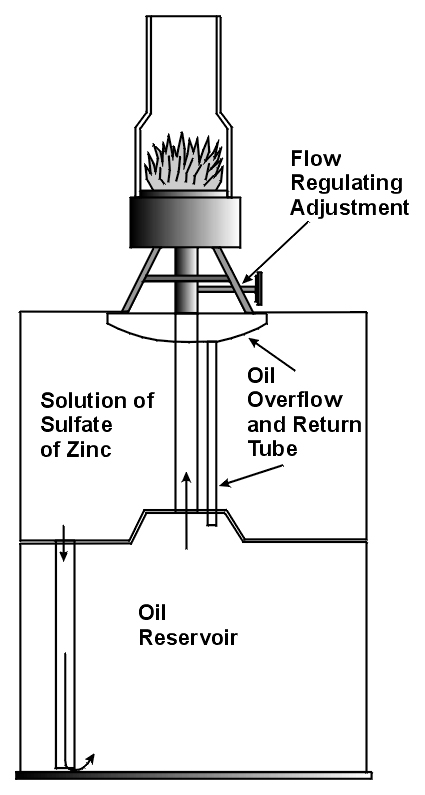

Thilorier invented an improved Hydrostatic Lamp. This lamp required the use of dissolved sulfate of zinc and a test instrument called an ‘Aerometer’ to test the density of the dissolved sulfate of zinc. Thilorier used the zinc sulfate in solution as the heavy liquid, which flowed down a tube below the oil. The oil actually floated on the zinc sulfate and was forced up a tube to the burner and on to the wicks. Any excess oil that overflowed the burner was collected and returned to the top of the oil tank by an overflow and return tube. The hydrostatic lamp was used to replace the early unreliable, clockwork driven, mechanical lamps in fixed lights where a reliable fountain or hydraulic style lamp could not be used due to its fountain and piping producing unacceptable shadows within the lens. The Scottish lighthouse service chose this lamp for use in all of their fixed lenses starting in the mid 1840s.

The main drawback to the hydrostatic lamp was that it functioned based on the relatively minor difference in the density (specific gravity) of the zinc sulfate vs. that of the oil. If the density of the zinc sulfate solution was not exactly correct the oil would not flow at all or would flow much too quickly.

(Drawing by Author) Thilorier’s Hydrostatic Lamp. (ca. 1840)

Hydraulic Lamps

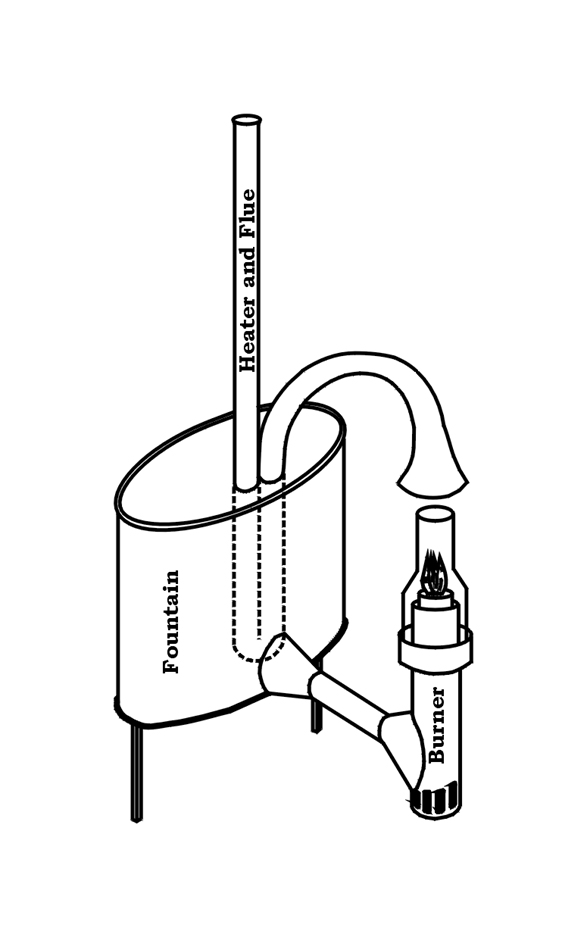

The hydraulic lamp was very similar to the fountain lamp and was used in all orders of lenses. It was based on gravity feed and consisted of a reservoir above the lens; another reservoir below the burner to contain the oil, which overflowed the burner; a pump to raise the oil to the upper reservoir, and the burner.

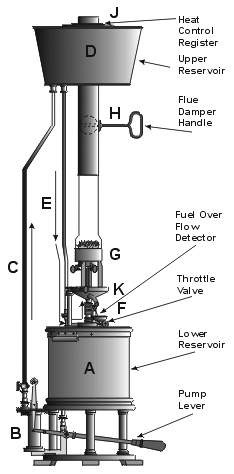

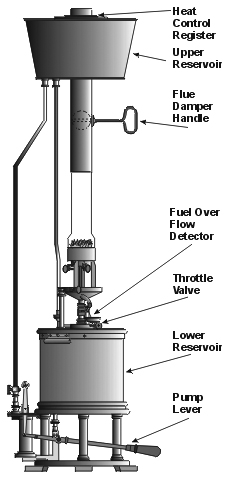

(Drawing by Author from Lighthouse Board Drawing) Hydraulic Lamp Overview.

General Operation of a Hydraulic Lamp

At the start of each day, the keeper removed all of the oil in the Lower Reservoir ‘A’. He would then fill the Lower Reservoir ‘A’ with clean fresh oil and close the Throttle Valve ‘F.’ The keeper then used the Pump Lever connected to Pump ‘B’ and pumped the fresh oil from the Lower Reservoir ‘A’ up through pipe ‘C’ into the Upper Reservoir ‘D,’ which held enough fresh oil for operation during the longest night of the year with some oil left over. The fresh oil filled the Upper Reservoir ‘D’ and then flowed down pipe ‘E’ to the Throttle Valve ‘F’ where it could flow no further. Note: in the hydraulic lamp designed by George Meade it was also possible to pump oil from a storage tank kept in the room below the lantern room instead of from the Lower Reservoir ‘A.’

In the evening the lamp was lit by opening the Throttle Valve ‘F,’ which allowed the oil to flow up a central tube passing through the oil Overflow Collector ‘K’ and into the Burner ‘G’ where it flowed through and over the wicks. The keeper lit the oil at the wicks and regulated the flow of oil by adjusting the Throttle Valve ‘F’ and by adjusting the height of the wicks by raising or lowering the wicks using the individual wick adjusting knobs on the Burner ‘G.’ The overflow of the oil passed over the concentric wicks and back down into the Overflow Collector ‘K’ and out a small tube into a Sensor Cup, which was a part of the Fuel Overflow Detector. An alarm bell was used with the lamps in Fresnel lens lights. It consisted of a lever that was pivoted like a teeter-totter. One end of the lever was raised and blocked the alarm mechanism. The other end of the lever held a small Sensor Cup with a small hole in its bottom. The Sensor Cup was located in the flow of the oil from the overflow of the burner. As long as oil overflowed the burner, the Sensor Cup was kept full of oil and the alarm lever was held in place. If the overflow of oil stopped, the Sensor Cup would cease to be filled and the oil within it would flow out through the small hole in its bottom. When this happened the alarm lever was no longer held in the up position and the end blocking the alarm mechanism lowered and the alarm would sound. The alarm usually consisted of a bell located in the tower or keeper’s quarters. After passing through the Sensor Cup the overflow oil was passed into the top of the Lower Reservoir ‘A’ through a small wire mesh strainer.

The air flow through the burner and chimney was regulated by hand adjusting the Flue Damper Handle ‘H.’ The Upper Reservoir ‘D’ had a cylindrical hole through its center. Through this hole a sheet-iron chimney passed down to the glass chimney. In the upper cover of the Upper Reservoir ‘D’ was a Heat Control Register ‘J’ that surrounded the sheet-iron chimney. When the register was open, the heated air passed through between the chimney and the reservoir, producing little effect upon the temperature of the oil. When it was closed, the heated air was obstructed and the oil was heated by it, so that in cold weather the oil was kept fluid enough to flow easily through the pipes.

The Wilkins Hydraulic Lamp (ca. 1839)

This lamp was composed of a reservoir to hold the required quantity of oil for use during one night, a supply cistern, and a burner. From the bottom of the reservoir a tube connected to the supply cistern. In the end of this tube was a movable stop, to which was attached a hollow metallic ball, which served, as the oil in the cistern rose or fell, to regulate the flow of oil in the cistern, and to the burner. The oil was fed from the supply cistern through a tube from the bottom of the cistern to the burner, and up to the concentric wicks. The overflow of oil flowed into the overflow cistern.

Meade’s Hydraulic Lamp (1853)

This lamp was designed by then Lieutenant George G. Meade, of the United States Corps of Topographical Engineers, and erected by him first at the Sand Key Lighthouse in Florida, and later at other locations. It should be noted that this was the same George G. Meade that would become the General leading the Union troops in the battle of Gettysburg, during the Civil War.

Meade’s lamp was intended to take the place of the French mechanical lamps of the Fresnel-Arago and Lepaute patterns, and do away with the pumps and clockwork machinery. This lamp was previously described in the section ‘General Operation of a Hydraulic Lamp.’

(Drawing by Author from Lighthouse Board Drawing) George G. Meade’s Hydraulic Lamp. (1853)

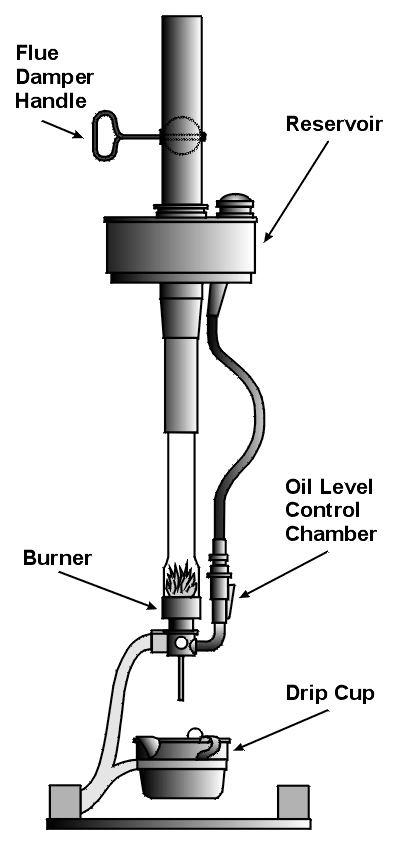

Franklin Hydraulic Lamp (1863) - for Fourth, Fifth, and Sixth Order Lights

This lamp was designed by Captain William B. Franklin, United States Corps of Topographical Engineers, and Engineer Secretary of the Lighthouse Board. It consisted of four principal parts:

1. An airtight reservoir, with supply tube attached, resting on the upper ring of lens.

2. The burner, with reception tube and oil level control.

3. A bracket, with a drip-cup fastened to the bottom ring of the lens.

4. An oil level control air chamber opening into the reception tube.

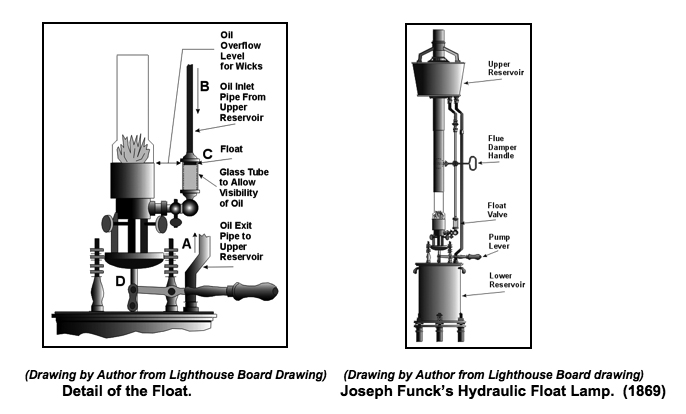

Joseph Funck created an almost identical lamp for use with fourth, fifth and sixth order lenses in 1869 that also used his float valve design to replace the oil level control chamber of the Franklin hydraulic lamp.

(Drawing by Author from Lighthouse Board Drawing) Franklin’s Hydraulic Lamp. (1863)

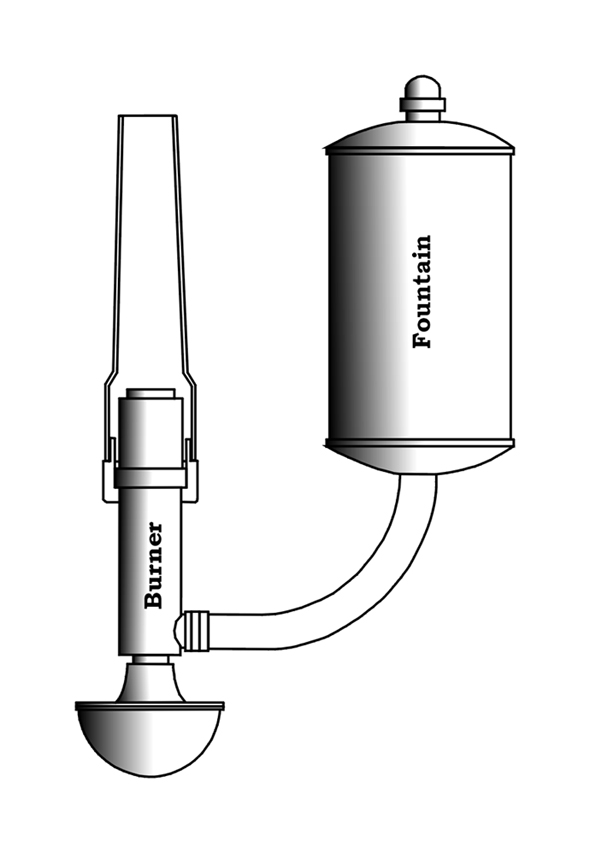

Funck’s Hydraulic-Float Lamp (1869)

The major successor to the French mechanical lamp, in America, was a lamp designed by Mr. Joseph Funck, the foreman of the American Lighthouse Service workshops at the depot on Staten Island, New York.

Funck’s hydraulic float lamp had a pump, operated by hand, that raised the oil from the Lower Reservoir to the Upper Reservoir through Pipe ‘A.’ The oil then flowed down from the Upper Reservoir through Pipe ‘B’ into the Float Chamber. The Float ‘C’ was donut shaped and floated upon the surface of the oil in the glass chamber. In the center of the Float ‘C’ a small needle was fixed that pointed upward into a specially shaped restriction in the oil inlet Pipe ‘B’ and when the Float Chamber was full of oil, the needle in Float ‘C’ blocked further flow of oil from Pipe ‘B’ into the Float Chamber. The oil flowed to the wick after passing through the Float Chamber. As the oil flowed into and over the wicks, some of it being burned, the oil in the Float Chamber lowered and the Float ‘C’ lowered allowing more oil to enter the chamber. The Float ‘C’ was adjusted so as to rise and close the oil inlet as soon as the oil reached the proper height to just overflow the wick, thus maintaining the oil always at the same level. The overflow oil passed down through an Overflow Collector ‘D’ into the top of the Lower Reservoir.

Funck’s 8-Day Lamp (1885)

In the early 1880s, there was a great need for lanterns that could be used as beacon lights on small piers and as post lamps, functioning as the warning lights for obstacles on the major inland rivers. The problem with the lamps, in use at the time, was their need for constant attention. In 1885, Joseph Funck developed the idea of adding a large circular tank for oil around the top of the lamp, giving it the capacity to operate for up to 8 days without attention. This design worked quite well, but the lamp itself was the old-fashioned flat wick variety and the lens was made of pressed glass of rather poor quality. The lamp was also susceptible to being blown out by strong winds.

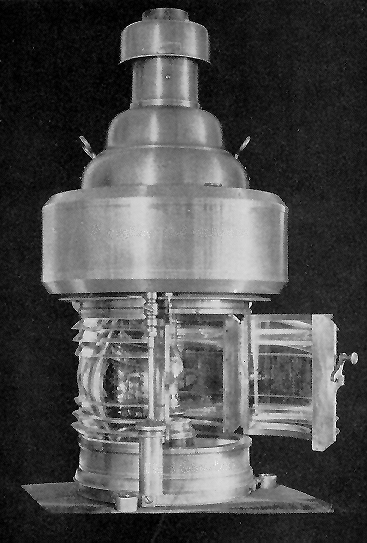

The 5-Day Lens Lantern developed and improved by David Heap.

Heap’s 5 and 8-Day Lamps (1889)

In 1889, David Heap developed a further improved design for the American 8-day lantern and invented a new 5-day lantern. He described his thoughts in a report to the Lighthouse Board as follows:

“The eight-day tubular lens-lanterns having proved quite successful so far as maintaining a light without attention during that length of time, I believed that it would be advisable to apply the same principle to a lantern with cut-glass prisms, using a lamp with a circular burner and a chimney, and thus obtain a much more powerful light.”

The Benson-Lee Automatic Lamp (1895)

By 1895 in Europe, the Benson–Lee automatic lamp was beginning to be used in beacons. It had special wicks that were tipped with carbon from tar and it required no trimming for four or five days of operation. It was chosen for all new installations in Scotland and acted like the American 8-day lamp. The Benson-Lee lamp replaced the earlier Trotter-Lindberg lamp developed in Sweden, which required significantly more technical knowledge to maintain.

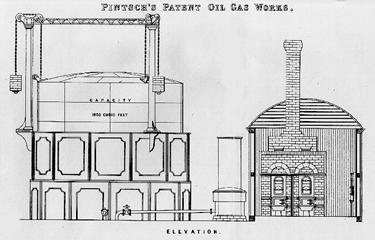

Gas Burners

Monsieur Phillip Le Bond d’Hambersin was given a French patent for producing illuminating gas from wood in 1799, which was made by carbonizing wood in a closed retort. He called his invention the Thermo Lamp, which was first used in the Le Havre lighthouse in France that year.

Oil gas was first used at the Holyhead lighthouse in Wales in 1820 and from 1819 to 1827 Fresnel and Arago experimented with the use of gas burners for use within the Fresnel lenses, however, they chose to continue with the use of their multi-wick oil lamps. Also in 1823, Pintsch gas was tried at the South Foreland lighthouse in England. All of these early experiments with gas used simple tube or multiple tube burners.

(Drawing by author from drawing in Oeuvres Completes de Fresnel) The Fresnel – Arago Gas Burner 1824.

A lighthouse built in 1829, known as the Barcelona light, and sometimes called the Portland light located on Lake Erie, was unique because of its fuel source. The nearby town of Fredonia, New York was the first site in North America to commercially use Natural gas, starting in 1821. The Barcelona lighthouse was located 18 miles west of Fredonia and for part of its life, it used a nearby ‘spring’ of Natural gas carried a distance of two miles in pipes to the tower to light its lamps. Unfortunately, the Natural gas gave out in 1838, and the gas lamps were removed.

An effort was made in 1841 to use another form of Wood gas known as Rosin gas at the Christina Creek light station, near Wilmington, Delaware. Rosin gas was made through the heating of pinesap (rosin) or pine logs in an enclosed retort. After about a year of trial, the effort at Christina Creek was abandoned as impractical.

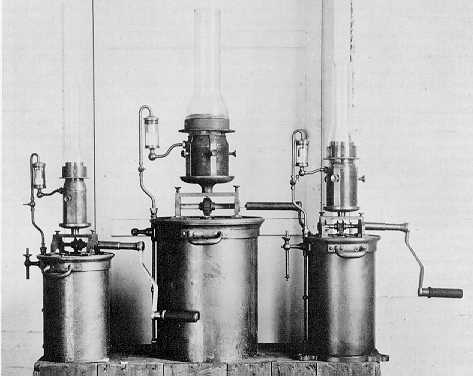

Gas was later used in lighthouses in a number of countries. However, its production, delivery, and excessive heat restricted its use to a relatively small number of lighthouse locations. The major drawback was the need for the building and operation of a gas production plant next to each lighthouse where it was to be used.

(Drawing from Trinity House Report on the Relative Merits of Electricity, Gas and Oil 1885)

A typical gas generation facility that had to be co-located with each lighthouse using gas.

Wigham’s Composite Gas Burner (1868)

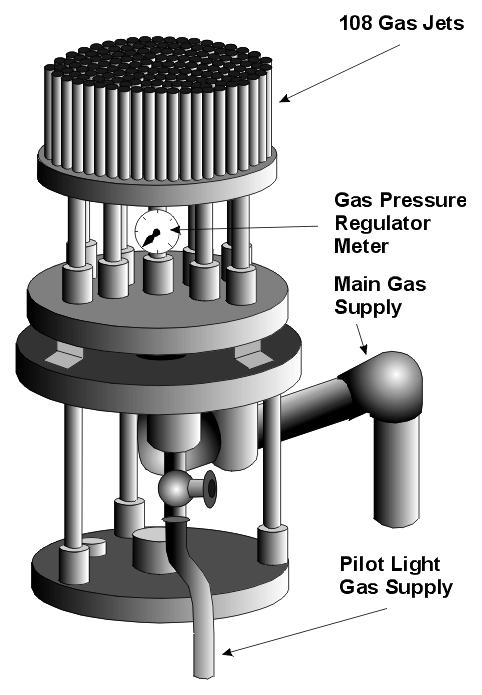

John R. Wigham developed many forms of lamps for use with coal gas in Ireland starting in 1865. His designs were the first that could be used reliably and which could be sized based on the size of the lens. Wigham’s designs ranged from 28 to 108 gas jets and several still larger numbers of jets were experimented with. Wigham’s gas lamps were used extensively in Ireland.

(Drawing by Author) John R. Wigham’s 108 Jet Composite Gas Burner. (1868)

Kerosene Burners

Doty’s Kerosene Burner (1868)

An American ship captain, Henry Harrison Doty, thought he could solve the problems related to the use of kerosene in lighthouse burners. He described his efforts as follows:

“In 1866, the idea occurred to me that if paraffin (Ed: kerosene) as now manufactured, with a large specific gravity and safety standard, could be employed in Lighthouse Illumination, a great reform in the economy and intensity of coast lights would be attained. I accordingly set myself resolutely to the solution of the problem, how this could be affected not only for the one wick burner, but for lamps having concentric wicks. After more than two years unremitting study and experiment, I was successful in discovering the means of doing this for all the different orders of burners, and that too, without causing any structural re-arrangement of the apparatus or lamp at present in use.”

Doty mentioned the specific gravity of the kerosene because the heavier the kerosene the less volatile it was, and therefore the safer it was to use.

French Five-Wick Lamp based on Doty’s patent. (ca. 1873)

The French Lighthouse Service had long been considered the leader in technical innovation and quality. Captain Doty took samples of his latest burners and went to Emperor Napoleon III in November 1868, convincing him of their advantage and requesting that France put them on trial. Doty’s request was granted and a trial within the French Lighthouse Service was begun in December 1868 and completed successfully in January 1869. A number of French lighthouses were then converted to kerosene as a fuel, with the Doty burner modifications. The French did not use the Doty burner directly. Instead, they bought the rights to use Doty’s design principals in their own burner designs.

Funck’s Kerosene Lamps (1876)

Early in 1874, Joseph Funck, the foreman of the Lamp Shop at the Tompkinsville New York Depot, was assigned to begin analyzing any changes necessary in the design of burners for the use of kerosene. Joseph Funck was given a patent for his version of the kerosene burner for lighthouses on November 28, 1876. Captain Doty was continuing to further describe his design and on March 28, 1877, he asked for a second reissue of his patent to describe some additional features of his original design that he felt Funck was infringing upon, and began a lawsuit against the Lighthouse Board and Funck. On December 5, 1878 there was a final decision of the Supreme Court of the District of Columbia. In this decision Funck and the Government won every point and Funck’s multi-wick design was declared to be free of any patent infringement related to H. H. Doty or anyone else. The Lighthouse Board now had the right to deploy Funck’s multi-wick kerosene burners throughout the system.

(Photo from National Archives 26-LG-16-38) American Two, Five, and Three-Wick Kerosene Lamps. These lamps are all of the moderator type.

Joseph Funck’s Four-Wick Lamp. (1883) This lamp is of the moderator type.

The French 10-Wick Kerosene Burner.

Acetylene

The Acetylene process was invented by a Canadian, Thomas Leopold Willson in 1892. Willson also invented the idea of generating Acetylene inside a buoy in 1904. Acetylene is also sometimes called Dalen gas. When Acetylene is employed in lighthouse work, the gas is either supplied in cylinders, or is generated on the spot.

In 1896, two Frenchmen, George Claude and Albert Hess developed a method to store compressed Acetylene by dissolving it in Acetone held in steel cylinders. In this system the gas is compressed into cylinders filled with a porous substance, and with acetone, a liquid having the remarkable power of absorbing at atmospheric pressure twenty-four times its own volume of acetylene gas. Its power to absorb the gas increases in proportion to the pressure, so that at a pressure of ten atmospheres it will dissolve two hundred and forty times its own volume of acetylene gas.

One of the first acetylene gas buoys in the world was designed by David P. Heap, engineer of the Third District depot, in 1897. Heap’s buoy used three tanks of compressed acetylene gas to supply a lens lantern, and was used in an experiment conducted in New York harbor.

An acetylene gas lamp was installed at the Cloch lighthouse, in Scotland around 1900, and the acetylene was used to operate everything from the domestic lighting, fog signals and the engine house to the lighthouse lamp itself. In America, a beacon equipped with a generator for producing acetylene gas from calcium carbide was placed in the Mobile Channel in 1902, and this was the first official use of acetylene gas by the American Lighthouse Service. Compressed acetylene was first officially used at Jones Rocks Beacon, Connecticut, and South Hook Beacon, Sandy Hook, New Jersey, in 1903.

In 1904, the development of dissolved acetylene was improved when John Höjer approached the Gasaccumulator Company (later known as the AGA Company), requesting them to redesign the current apparatus. Mr. Gustaf Dalen of Stockholm, Sweden solved the problem with his development of the AGA compound for storing the gas in cylinders. He also invented the acetylene flasher in 1905, which drastically reduced the amount of gas used. An experimental buoy of the Swedish Pilotage Board was installed at Kalmarsund, showing a fixed acetylene light in 1905. In the following year the buoy was first fitted with the Dalen flasher. The Dalen flasher reduced the amount of gas consumed and was proven to need little maintenance.

The American Lighthouse Service chose the Willson carbide-water buoy design rather than the pressurized acetone cylinder type. In the Willson buoy the gas was made on the spot by sliding solid calcium carbide through a canvas chute into a fuel chamber in what was known as the ‘charging process’. This process was very dangerous and in 1913 an explosion occurred when refilling such an acetylene chamber in a buoy on the tender Hibiscus. Later, America abandoned the Willson design and began using pressurized cylinders throughout the American Lighthouse Service.

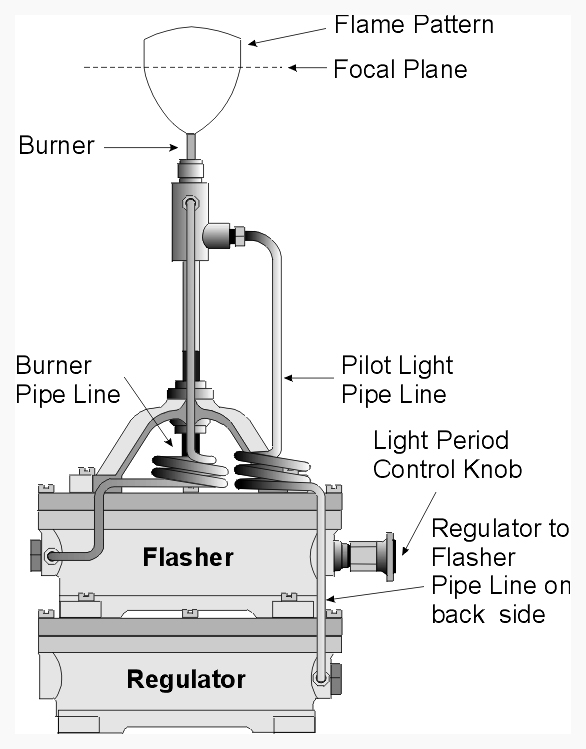

(Drawing by Author) Acetylene Regulator Flasher Lamp.

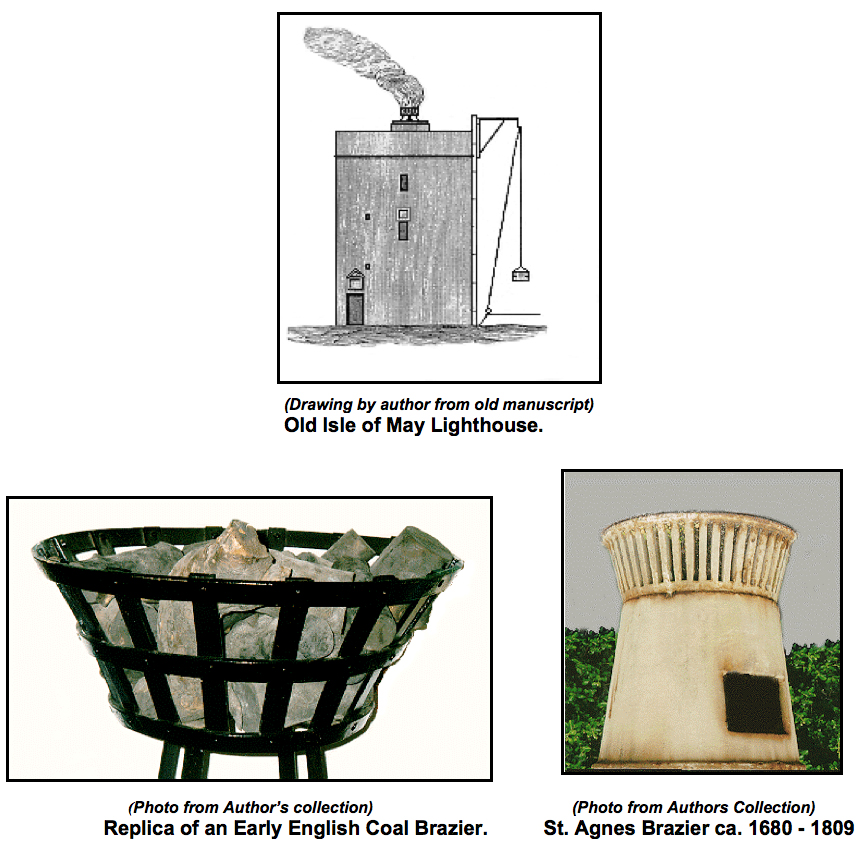

Sun Valve

The invention of the sun valve became critical to the expanded use of acetylene in lighthouses. Dalen invented the Sun-Valve in 1907 to still further increase the time between gas cylinder replacements. The Sun-Valve consisted of an arrangement of reflective gold-plated copper bars supporting a suspended absorbent black rod. The central black rod absorbs heat from the sunlight and expands closing a small valve at its base and shutting off the supply of gas to the burner (a pilot light is always maintained). When darkness approaches the heat is reduced and the black rod contracts opening the valve and allowing full flow of gas to the burner. The central black rod can be adjusted, by means of a screw, and the entire sun-valve is enclosed in a heavy glass cylinder. The first sun-valve was put into operation in the little Furuholmen lighthouse near Stockholm in 1907. Later sun-valve designs eliminated the reflective gold-plated bars to reduce the cost of the sun-valve assembly.

An American Sun Valve in its Protective Cage.

In England, Sir Thomas Matthews created a special clockwork mechanism that was able to time the flash cycles and the turn-on and turn-off times of unattended lights using acetylene fuel. The clockwork was wound automatically by the same mechanism that powered the lens rotation. While its intention was to function similarly to the sun valve, it could not react to storms as the sun valve could, nor was it able to be placed in the open or on buoys.

Matthews’ Acetylene Control Clock. The acetylene control valve is at the left center.

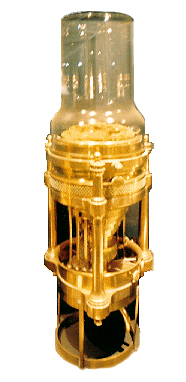

Incandescent Oil Vapor Lamps

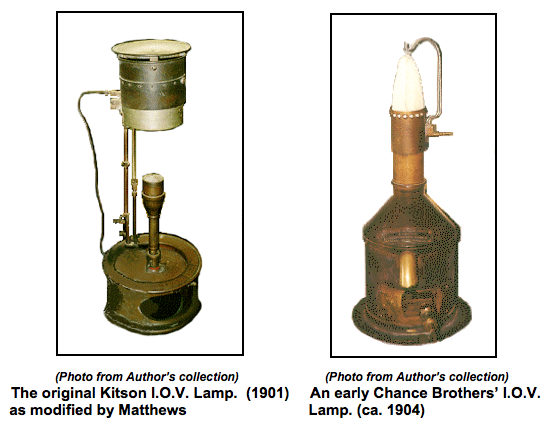

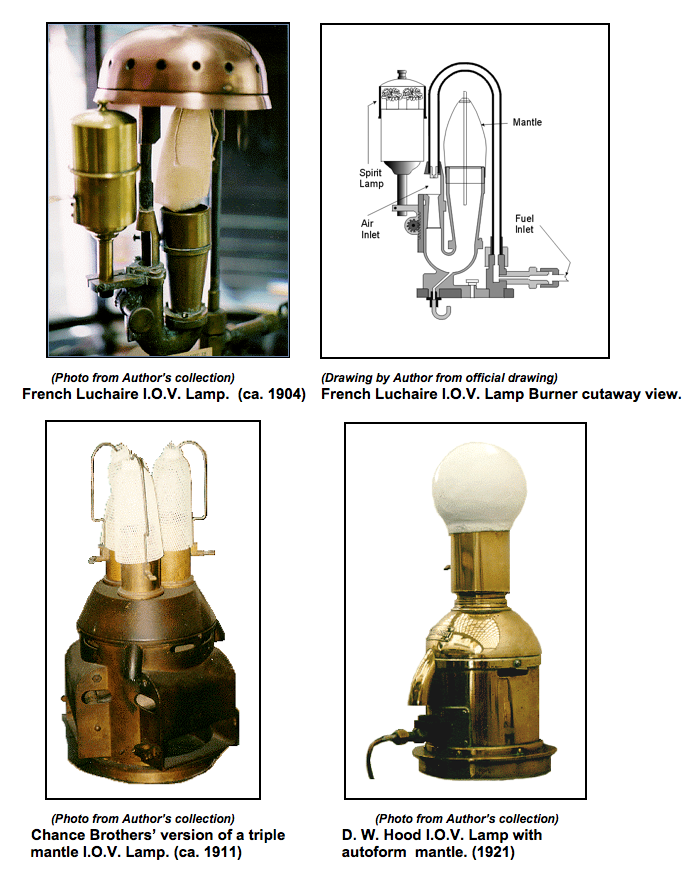

One of the first lamps burning gasified oil was developed by Nyberg and Lyth in Sweden in 1881. It worked by vaporizing colza oil and burning it without a mantle as a Bunsen burner does. However, this type of lamp was not efficient at producing additional light output. The next step was the addition of the incandescent gas mantle invented by Carl Auer von Welsbach, in Vienna, in 1885. This led to the first crude kerosene Incandescent Oil Vapor (I.O.V.) lamp, which was installed at the L’lle Penfret lighthouse, by the French, in 1898. It used air pressure and a fuel vaporizer tube where the kerosene was preheated into a fine vapor before it was ignited as a flame. This dramatically increased the oxygen at the flame and provided a brighter flame using less fuel.

In 1901, Arthur Kitson, an American, invented an improved burner in which the oil was converted into vapor under pressure in a retort and then mixed with air in a mixing chamber to form a gas for heating a mantle made of platinum gauze. The platinum gauze quickly carbonized and within a short time Kitson abandoned it in favor of a Welsbach style incandescent mantle made of silk impregnated with zirconia. This lamp produced at least three times the light output of the Argand style lamps previously used. Another similar incandescent burner was developed by C. W. Scott, the engineer to the Commissioners of Irish Lights in 1902, and still other versions were developed by Sir Thomas Matthews, engineer to the Trinity House in England, Pintsch in Germany and by Luchaire in France and Diamond in Canada. The I.O.V. lamp was first used in America at the Sandy Hook lighthouse in 1904. Matthews, in England, invented the triple mantle I.O.V. lamp around 1904 and the American Lighthouse Service began testing this lamp in 1913. One of these lamps was first used in America in 1916 at the Cape Lookout lighthouse. Finally in 1921, David Hood further improved and simplified the Kitson burner.

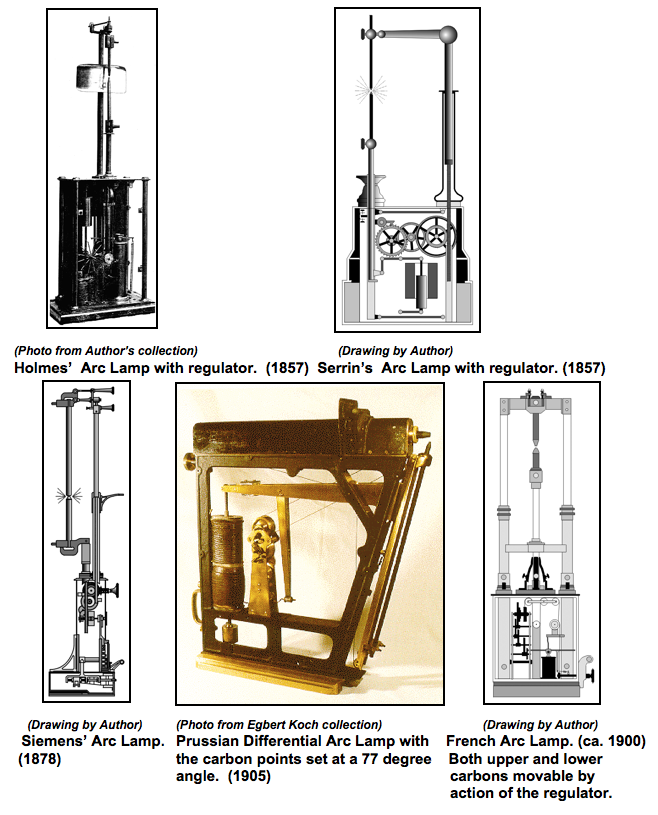

Electricity

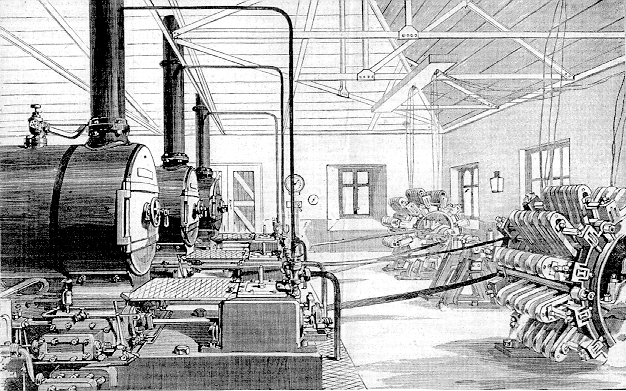

Electricity was not available in lighthouses before 1857. The electric arc had been demonstrated by Sir Humphry Davy in 1808-9. François Arago, who worked with Augustin Fresnel to develop the multiple-concentric-wick-oil lamp, also worked on the arc lamp during 1820. In 1836, Michael Faraday suggested that trials be made using arc lamps in lighthouses in England; however, it was not until 1853, when Professor Holmes made the first crude magneto-electric generator to power an arc lamp for use in a lighthouse. The first trial of this machine was made by the Trinity House, in England, in 1857. Also in 1857, Monsieur V. L. M. Serrin, in France, invented an arc lamp with automatic adjustment of the carbon rods through the use of a clockwork mechanism and electrical solenoids. Serrin’s lamp was further improved by Monsieur Lontin.

In 1858, at the request of Professor Faraday, an Alliance magneto-electric generator, modified by Professor Holmes, was tested at South Foreland lighthouse, in England, and the electric arc light was first shown to the mariner. Holmes’ machine was able to generate electricity, which was applied to two tiny 6 ¼ mm.-square-carbon rods between which a spark, or arc, was drawn by means of the electric current. The intense heat generated by the electric current liquefied a portion of the carbon rods as the current passed from one carbon point to the other. The carbon points had to remain the same distance from each other in order for the lamp to properly function. Serrin’s clockwork mechanism was designed to move the carbon rods and maintain the distance for the electric arc.

The electric-arc lamp was officially installed at Dungeness, England (old tower) in 1862, a Serrin lamp was first used in France at the Cape La Heve lighthouse in 1863, and other installations soon followed. In America, experiments with the Electric light in 1868 included the use of a magneto machine made by Mr. Wilde of Liverpool. Progress was also being made in other countries. In Germany, Werner Siemens invented the dynamo generator in 1866, which proved far more reliable than the generators previously used.

In 1869, Professor Holmes constructed a new dynamo-electric generator for Trinity House. The invention of the dynamo brought the first break-through in electric lighting by supplying a constant and reliable current to feed the lamp. The second breakthrough was the development of carbon rods with softer cores in 1877. These new style carbon rods had the ability to more easily maintain the arc in the center of the rod, giving a brighter and steadier light.

Various experiments were carried out in 1876-77 and again in 1883-84 at South Foreland to determine the best machine for generating electricity and to compare electric lights with oil and gaslights. Later, in 1885, three De Meritens alternating-current magneto generators along with three arc lamps of the Duboscq-Gaiffe model were put on trial.

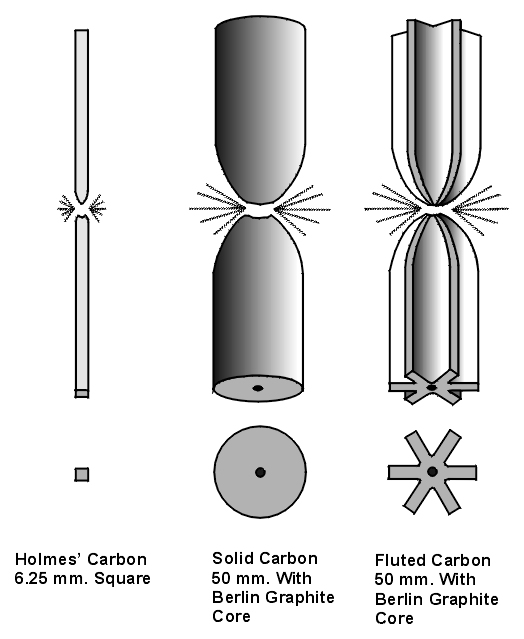

The carbon rods first used were the De Meritens pattern, square in section and made up of smaller carbons. These carbons were found ineffective, because the interior of the upper carbon had a tendency to fall out as the bands binding it together burned up during the consumption of the carbon. Later, cylindrical carbons up to 40 millimeters in diameter were used, the most effective being the 30-millimeter Berlin core carbon, which had a core of graphite 3 millimeters in diameter. Sir James Douglass invented a rod with fluted sides that provided additional steadiness to the arc, and soon larger carbons up to 50 millimeters diameter were tried.

The brilliance of the arc lights far exceeded any earlier oil lamp, but there were differing views about their penetration ability during fog. It was first thought that light produced from electricity would not penetrate fog to anywhere near the extent that the light from an oil lamp could, because the oil lamp produced a light that was strong in the yellow-orange-red part of the spectrum and the light from the electric arc was in the blue portion of the spectrum. Later, this was found to be false through the trials held at the South Foreland Lighthouse in 1884.

In America, experiments were also conducted on electricity and arc lamps during 1885 and the Lighthouse Board reported on the experiments as follows:

“It will be necessary to state first the reasons, which appear to have prevented the adoption in our service of electric lighting apparatus of the pattern now being introduced to a considerable extent in the lighthouses of foreign countries. The principal objections to the adoption of the new light, in its present form, are the expense of installation and the increased cost of maintenance.

For the present at least, and until the complete reliability of the new light under the keepers’ management shall be established, the advantage offered by an electric light, while being greatly superior in intensity to the oil lamp, would require alteration of the lantern or lens. The construction of an incandescent electric lamp adapted for this purpose, and designed so as to give the maximum amount of illumination in the most efficient direction, would best meet our needs. In the progress of this work many serious difficulties were encountered, but a practicable lamp much superior in luminous intensity and compactness to the first-order flame was produced. But, a lamp with satisfactory luminous intensity, justifying the establishment of a steam-plant to produce it, has not yet been attained, although there has been continued progress in this respect.

Regarding the superiority of the arc-electric light over all other modes of illumination yet developed for primary seacoast lights there can no longer be any question. This fact was definitely established by the very exhaustive experiments made at South Foreland, England, by a committee of the Trinity House, as stated in their report of August 1885. It is further sustained by the increasing number of electric lighthouses in actual operation and the favor with which they are received by mariners.

The first electrically lit light in America was the Statue of Liberty in 1886. The statue served as a lighthouse beacon for seventeen years.

The first American buoy lit with electricity was a series of spar buoys in Gedney’s Channel in New York harbor in 1888. Unfortunately the underwater power cables kept breaking and the project was finally abandoned in 1903. The electric light was first installed in an American lighthouse at Navesink in 1898.

America’s first lightship using electric illumination was the Cornfield Point light-ship, No. 51, delivered to the Staten Island Depot in July 1892. The Lighthouse Board reported that the lightship operated in a highly satisfactory manner when deployed. Tests were also run on the electric light at Hallet’s Point NY, known as the Hell Gate electric light.

In 1905, the Germans (Prussians) invented the ‘Differential Arc Lamp,’ where the positive carbon rod is held horizontally and the negative carbon rod is placed at a seventy-seven-degree angle to the positive rod. The German engineers felt that the Differential Arc Lamp allowed better control of the arc within the focus of a reflector or lens.

Arc Lamps

(Drawing by Author) Some of the Types of Carbon Rods used in Arc Lamps.

The carbon rods used in Arc lamps varied in size based on the amount of electrical current applied.

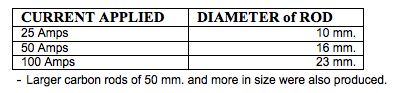

De Meritens Magneto Generator

The French De Meritens magneto generators were found to work with great steadiness and with good efficiency, revolving at 600 rpm. A De Meritens magneto was installed at the Lizard lighthouse, in England, and was used from 1881 until May 1950. It produced 32v at 120 cycles, giving an AC output of 3.5kw, and ran the arc lights at the station until 1926. The arc lights were then replaced with filament bulbs of 3kw, and the voltage from the De Meritens generator was transformed up to 80v.

(Drawing from old newspaper) Steam Engines and De Meritens Generators in the Generator Room at the Lizard Lighthouse, England. (1881)

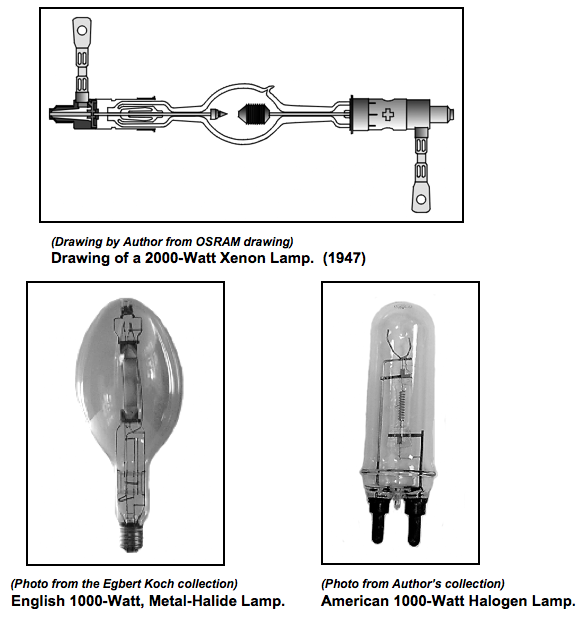

Modern Electric Lamps

The early incandescent light bulbs were very unreliable and while they were experimented with at many locations they were not put into use. It was after Thomas Edison invented the tungsten filament light bulb that similar (but much larger) bulbs were used in lighthouses. Bulbs of 1000-3000 watts replaced arc lights in many lighthouses in the early 1900s.

When commercial power became available the first station to be connected in England was South Foreland, and in 1922 it became the first British lighthouse to be lit by an incandescent lamp. These early lamps had very large globes and optical difficulties were encountered as the filaments presented a complex patterned light source, later bulbs became smaller and the filaments were made smaller as well. The Xenon discharge lamp, first introduced in 1947, gave a highly concentrated light source. It has one drawback in that its beam is very vertically narrow and the beam provides little, if any, of the ‘loom’ in the sky that mariners prefer to see. Later, in the Terschelling, Brandaris and other Dutch lighthouses, old incandescent bulbs were replaced by a super-high pressure mercury-iodine lamp, and in the United States, and elsewhere, various forms of Halogen lamp bulbs are now the norm.

Bulbs

(Photo from the Egbert Koch collection) Modern Lamp Bulbs in a Dual Changer.

The light sources used in lighthouses changed significantly over the years. Many styles of light sources were tried, some were a great success and some proved of little value. Yet all forms, ‘From Braziers and Bougies to Xenon,’ helped to make the lives of the mariners safer.

A Note About Candlepower

The determination of the light output of lamps is usually measured in candlepower. In the early years of lamp development there were no accurate methods of measuring candlepower and later, in the early 1800s the methods used were very subjective and unscientific by our current standards. The candlepower is also dramatically affected by the size of the flame, the type of oil used as a fuel, the maintenance of the lamp and polish of the reflector and by other factors such as the clarity of the air and alignment of the reflector with the horizon. In describing the various apparatus in this story I have used the candlepower ratings developed or estimated by the various inventors. However, the candlepower ratings should only be used as a very rough estimate of the relative power of each instrument as compared to the others and not as a true rating of its actual light output.